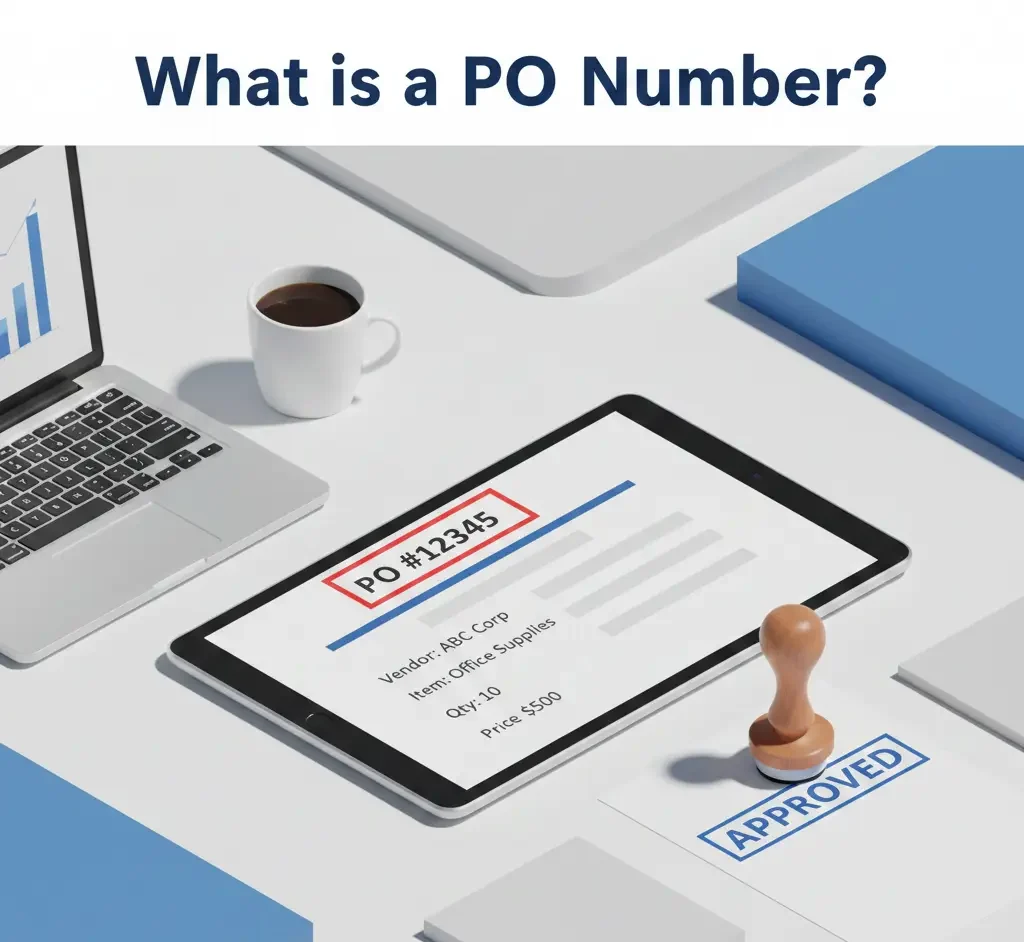

Every construction project generates hundreds of small purchasing decisions for materials, equipment, services, and subcontracted work. What keeps all of that organized isn’t guesswork or memory. However, its structure, which starts with a PO number.

What does PO stand for in Business?

PO stands for Purchase Order. It’s the formal document a buyer issues to authorize a purchase. The PO number becomes the reference used by procurement teams, suppliers, and accounting to confirm what was approved and what should be paid.

What is a Purchase Order?

Before we dig into PO numbers, it helps to understand the document itself. A purchase order (PO) is more than just a number; it’s a formal agreement that tells suppliers exactly what a business is buying, in what quantity, and at what price.

What is a Purchase Order in Procurement?

A purchase order is a document issued by a buyer to a supplier. It confirms:

- What products or services are being purchased

- The agreed price

- Delivery timelines

- Payment terms

You can consider it a formal green light to spend. Once it’s approved, everyone knows the purchase is authorized.

Understanding how a purchase order fits into the bigger system becomes easier when you look at the full procurement process flow and how organizations control purchasing from request to payment.

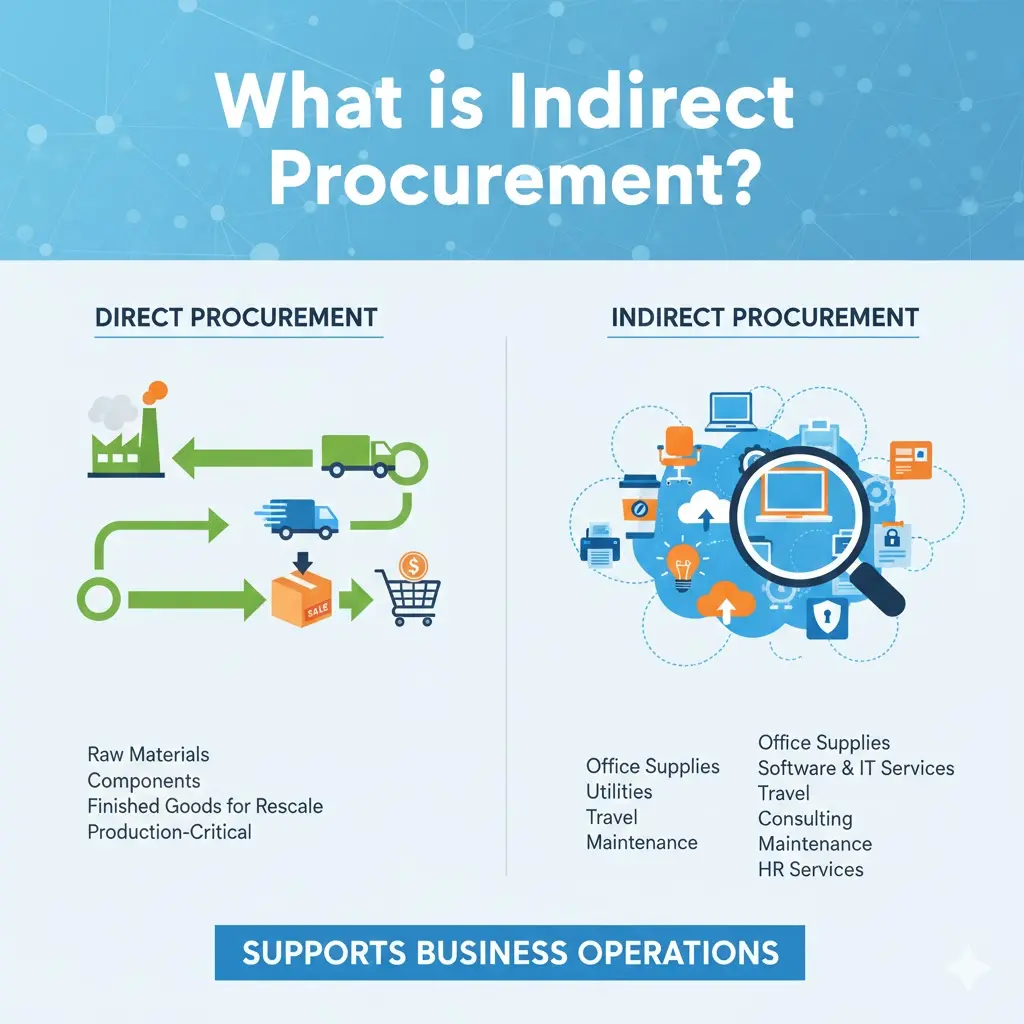

PO vs Purchase Requisition vs Contract

It’s easy to mix these up. Here’s a comparison:

| Document | Who Creates It | When It’s Used | Legal Obligation |

| Purchase Requisition | Internal team | To request a purchase internally before approval | Not legally binding; internal request only |

| Purchase Order (PO) | Procurement/Buyer | After approval, to authorize a supplier | Becomes binding once accepted by the supplier |

| Contract | Legal/Procurement | For long-term agreements, recurring purchases, or large projects | Legally binding once signed by both parties |

What is a PO Number?

A PO number (purchase order number) is a unique identifier assigned to a purchase order. It tracks an approved purchase from pro procurement through invoicing and payment. One number ties everything together.

Why PO Number Matters?

Projects involve multiple vendors, overlapping timelines, and strict budgets. Without a consistent PO number system, it becomes difficult to verify approvals, match invoices, or trace spending. That’s where risk shows up in the form of duplicate payments, unauthorized purchases, and audit gaps.

A well-managed PO system helps teams:

- Control spending before invoices arrive

- Reduce payment errors and disputes

- Maintain clear audit trails

- Support compliance with internal controls

- Improve coordination between procurement, site teams, and finance

So while a PO number may look simple, it plays a critical role in cost control, risk management, and compliance across construction projects.

Structure of a PO Number

Understanding the structure of a PO number is essential before you start assigning them. It’s not random; it’s a system designed to make tracking, reporting, and auditing easier.

Common PO Number Formats

Most procurement companies use one of two formats:

| Sequential Numbering | Alphanumeric Numbering |

|

|

Breaking Down a PO Number: PRO-2026-001

Let’s see what each part means:

| Part | What It Means |

| PRO | Company code or project code |

| 2026 | Year the PO was issued |

| 001 | The first PO was issued that year |

So, at a glance, anyone can see who issued it, when, and which order it is. No confusion, no guesswork.

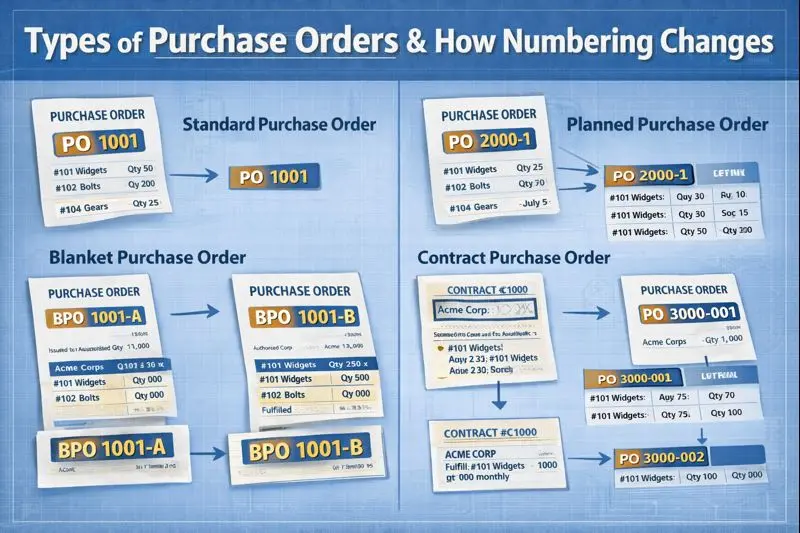

Types of Purchase Orders & How Numbering Changes

Not all purchase orders are the same, and the type you choose directly impacts how it’s numbered, tracked, and invoiced. Understanding these differences is essential for smooth procurement.

● Standard Purchase Orders

A standard purchase order is the simplest type. It’s used for a one-time purchase of materials or services. Numbering is usually sequential or alphanumeric, like PRO-2026-012, making it easy to track.

For example, if a construction team orders 100 cubic yards of concrete for a single project, a standard PO ensures everyone knows exactly what was approved and prevents confusion during delivery or invoicing.

● Blanket Purchase Orders

Blanket purchase orders are designed for repeated purchases over a set period from the same supplier. Instead of creating a new PO for each delivery, the main PO receives a number, and individual releases often get a suffix, such as BL-2026-001-R1.

For instance, if steel beams are delivered monthly for six months, the blanket PO keeps all orders connected under one main reference, simplifying tracking and approvals.

● Planned Purchase Orders

Planned purchase orders are pre-approved for recurring materials or services, even if the exact quantity or delivery date isn’t finalized yet. They often follow a separate numbering sequence to differentiate them from standard POs.

An example is ordering construction essentials like nails, bolts, or lumber for multiple upcoming projects. This approach allows procurement to prepare ahead without issuing multiple one-off POs.

● Contract/Framework Purchase Orders

Contract or framework POs are issued under a larger agreement. These usually reference the contract number, such as CON-2026-045, making it easy to link individual POs to the broader agreement.

For example, a multi-year HVAC installation project across several buildings would use a framework PO to manage each order while maintaining consistency with the overall contract terms.

● Service Purchase Orders

Service purchase orders are used when hiring labor or contractors rather than purchasing materials. They often include codes to identify the type of service, such as SV-2026-009.

For instance, a plumbing subcontractor brought in for a specific project would receive a service PO to formalize the purchase, track costs, and ensure proper payment.

● Drop-Ship Purchase Orders

Drop-ship purchase orders are used when the supplier ships directly to the construction site or client. The PO number often includes a site or client code, like DS-NY01-2026-003, to track deliveries.

A common example is having custom windows shipped straight to a building site, bypassing the warehouse.

Framework-based POs often fall under broader category management strategies, where similar purchases are grouped to improve supplier relationships and pricing.

The PO Lifecycle

A purchase order isn’t just a number; however, it’s part of a process that tracks every step of a purchase, from creation to closure. Understanding the lifecycle helps construction teams stay organized, avoid errors, and make sure invoices match orders.

1. PO Creation & Approval

Every PO starts with creation. A project team identifies what’s needed, like materials, services, or equipment, and submits a request to procurement. Once procurement reviews and approves it, the PO is issued.

This stage sets the rules for quantity, price, delivery date, and payment terms. And approval ensures that only authorized purchases move forward.

Also, here come two types of POs

Issued vs. Acknowledged POs

Once the PO is sent to a supplier, it can have one of two statuses: issued or acknowledged.

- Issued means the PO has been created and sent, but not yet confirmed by the supplier.

- Acknowledged means the supplier confirms receipt and agrees to the terms.

This step is important because it ensures both parties are aligned before any delivery or invoice is generated.

2. Partial Receipts & Backorders

Not all orders arrive at once. Sometimes deliveries are partial, or items are backordered. The PO number tracks each partial shipment, so finance and the project team know what has been delivered and what is still pending.

The PO Status Flow

● Amended/Revised POs

Sometimes a PO needs changes in quantity, price, or delivery date. These are amendments or revisions.

Rules for Amendments/Revisions

- Each revision should be documented and often gets a version number (e.g., PRO-2026-012-V2).

- Keeping revisions tied to the original PO number maintains a clear audit trail.

● Closed, Cancelled, & Archived POs

A PO is considered closed when all items are received and invoices are paid.

- Cancelled POs are those that will not be fulfilled due to project changes or errors.

- Archived POs are stored for record-keeping and audits.

Tracking these statuses ensures that only active, valid POs remain in circulation, preventing duplicate payments or confusion.

A structured PO lifecycle is a core part of effective spend management, helping organizations monitor where money is committed before invoices even arrive.

Number vs Invoice Number

Many people mix up a PO number and an invoice number, but they serve different purposes. Understanding the difference is key to keeping procurement, finance, and project teams aligned.

Here’s a simple table to show the differences:

| Feature | PO Number | Invoice Number |

| Who generates it | Buyer/Procurement | Supplier/Vendor |

| When it’s issued | Before the purchase or delivery | After goods or services are delivered |

| Purpose | Authorizes a purchase and tracks approval | Requests payment for delivered goods or services |

| Who uses it | Buyer, finance, supplier | Buyer, finance, accounts payable |

| Legal significance | The binding document, once accepted by the supplier | Evidence of payment due |

The End-to-End Workflow of PO Number & Invoice Number

Here’s how the PO number and invoice number work together:

- Buyer issues PO: Procurement creates a purchase order with a unique PO number and sends it to the supplier.

- Supplier references PO: The supplier confirms the order and prepares the delivery. Every invoice sent must reference this PO number.

- Invoice sent back with PO number: Once goods or services are delivered, the supplier sends an invoice. Finance matches the invoice to the PO number to ensure everything aligns before payment.

This workflow is especially important in construction, where multiple deliveries, partial shipments, and revisions are common. The PO number ensures that every invoice can be traced back to an approved purchase, reducing disputes and errors.

Invoice Matching & Financial Control

One of the main reasons a PO number exists is to make sure payments are accurate and controlled. Without it, construction projects risk paying the wrong amounts, paying twice, or struggling during audits.

Why PO Numbers Enable Invoice Matching

A PO number links the purchase approval, the delivery, and the invoice. When finance teams see a PO number on an invoice, they can instantly check:

- Was this order approved?

- Were the correct items delivered?

- Does the invoice match the agreed price?

This simple number cut mistakes before money leaves the account.

3 Common Types of Invoice Matching

● 2-Way Matching

2-way matching compares the PO and the invoice. It also checks that what was ordered matches what the supplier billed and is good for small or straightforward purchases.

Example: Ordering 50 sheets of drywall. The invoice matches the PO quantity and price.

● 3-Way Matching

3-way matching adds the receiving report to the process. It compares the PO, the invoice, and what was actually delivered. And this is standard in construction because partial shipments and backorders are common.

Example: A PO for 500 concrete blocks is partially delivered (300 received). The invoice should reflect only what was delivered.

● 4-Way Matching (Advanced Controls)

4-way matching includes the inspection or quality approval on top of the first three documents. This ensures not only that the quantity is correct, but that materials meet specifications, and is useful for high-value or safety-critical items.

Example: Structural steel beams must pass inspection before payment is approved.

Issues With Invoice Matching

Matching isn’t always perfect. Minor differences, like a few extra bolts or small pricing adjustments, are allowed within tolerances. Simply put, invoice matching experience issues due to tolerances, variances, and disputes.

How to Avoid Issues?

Make sure that:

- Tolerances define acceptable differences between the PO and the invoice.

- Variances outside the tolerance trigger a review before payment.

- This ultimately prevents disputes, overpayment, and unauthorized spend.

A consistent PO system makes it easy to catch these issues automatically, saving time and protecting your budget.

This structured linkage between approval and payment is a key part of end-to-end procurement, where every stage of purchasing is connected for full visibility.

Why Your Business Needs a Strategic PO System

A well-structured purchase order system isn’t just about organization; however, ot’s a cornerstone of financial control, compliance, and efficiency in construction procurement. Here’s why investing in a strategic PO system matters.

● Audit Trails and Transparency

Every PO you issue leaves a clear record. From creation to payment, the PO number tracks every step. This transparency makes it easier for finance teams and project managers to see what was purchased, when, and by whom.

For example, if an auditor asks for documentation of a large equipment purchase, a properly numbered PO provides the full trail, and no hunting through emails or spreadsheets.

● Fraud Prevention and Duplicate Payment Control

Fraud and duplicate payments are real risks on busy projects. A strategic PO system prevents both by:

- Ensuring each PO number is unique

- Matching invoices to approved POs before payment

- Flagging any duplicate or suspicious entries

For instance, if a supplier accidentally sends 2 invoices for the same delivery, the PO system immediately highlights the mismatch, preventing overpayment.

● Legal Protection

A PO is more than internal paperwork, as it can serve as a binding commercial offer. Once a supplier accepts it, both parties are legally bound to the terms specified, including pricing, delivery schedules, and payment terms.

This protects your business if disputes arise. For example, if a supplier fails to deliver materials on time, the PO acts as evidence of the agreed-upon terms.

● Budget Control and Spend Visibility

A strategic PO system gives managers a clear view of what’s being spent, where, and by whom. By linking every purchase to a PO number, you can:

- Track expenses by project, cost center, or department

- Compare actual spending to budgets

- Make informed decisions before approving new purchases

In construction, this means avoiding unexpected cost overruns and keeping projects profitable.

A structured PO system also supports broader procurement process improvement efforts by standardizing how purchases are approved, tracked, and analyzed.

● Preventing Maverick Spend

Maverick spend happens when team members buy items outside the approved process. A structured PO system eliminates this by requiring:

- Requisition approvals before issuing a PO

- Unique PO numbers for all purchases

- Clear matching of invoices to POs

As a result, every purchase is authorized and visible, reducing unauthorized spending and financial risk.

Common PO Number Mistakes

Even with the best intentions, procurement teams often make mistakes with purchase orders. These errors can cause delays, overspending, or audit headaches. Knowing the common pitfalls helps you prevent them before they happen.

● Duplicate PO Numbers

Duplicate PO numbers occur when the same number is issued for two different purchases. It causes confusion in finance, delays invoice matching, and increases the risk of double payments.

How to avoid it:

Use sequential numbering or automated PO software that enforces uniqueness. Always check the last number issued before creating a new PO.

● Reusing Closed PO Numbers

Reusing numbers from previously closed or cancelled POs is another common mistake. This makes audit trails unclear and can create disputes if suppliers reference old numbers.

How to avoid it:

Archive closed POs and continue the sequence without overlap. Versioning helps track amendments without reusing numbers.

● Invoices Without PO References

Invoices that don’t reference a PO make matching difficult. This delays payment, increases disputes, and may allow unauthorized purchases to slip through.

How to avoid it:

Require suppliers to include the correct PO number on all invoices. Integrate PO systems with AP workflows for automatic matching.

● Non-PO Spend Leakage

Purchases made outside the approved PO process, often called maverick spend, can add up quickly. This creates untracked expenses, undermines budget control, and increases audit risk.

How to avoid it:

Enforce policies requiring all purchases over a threshold to go through the PO system. Track non-PO spend and address recurring issues with departments.

● Poor Supplier Communication

Even with the right PO system, miscommunication with suppliers can cause errors. This leads to incorrect deliveries, wrong pricing, or missed acknowledgements.

This issue often leads to hidden procurement costs due to delays, disputes, and manual processing work.

How to avoid it:

Confirm PO receipt, track acknowledgements, and use electronic communications (like EDI or supplier portals) when possible.

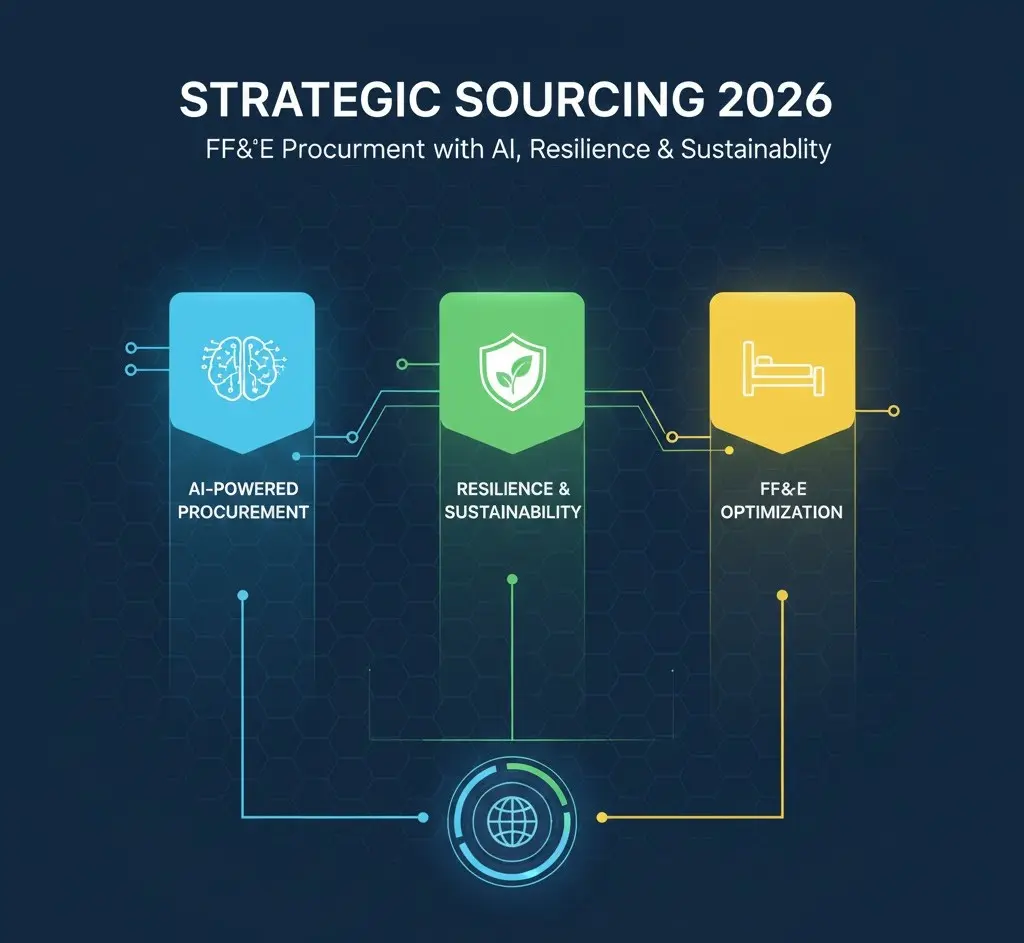

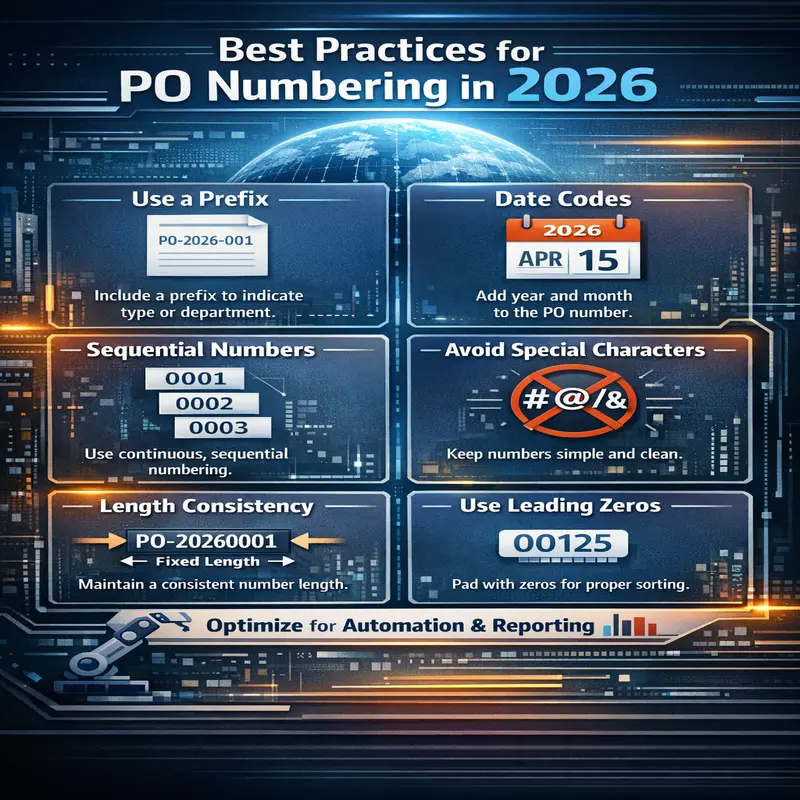

Best Practices for PO Numbering in 2026

A well-thought-out PO numbering system keeps procurement organized, reduces errors, and ensures audit-ready records. In construction, where multiple projects, suppliers, and departments interact, the right system is crucial.

● Keep It Short and Logical

Simplicity is key. Long, complicated PO numbers may seem precise, but they often confuse. Short, logical numbers like NY-2026-015 are easy to read, enter, and track. They allow faster data entry with fewer errors and easier cross-team communication. According to Procurement Leaders, clear numbering improves approval times by up to 20%.

● Avoid Over-Engineering the Format

Overly complex formats often require manual corrections that slow down procurement. In other words, it’s tempting to add codes for every possible variable, like project, department, supplier, material type, but too many elements can backfire.

Therefore, you must stick to the essentials, including project/site code, year, and sequential number. This keeps tracking simple, reduces mistakes, and allows for easier system integration.

● Standardization Across Departments

All teams, including procurement, finance, and project management, should use the same numbering logic. Standardization ensures that everyone interprets the number consistently.

This also streamlines approvals, reduces duplicate POs, and provides clearer reporting across projects. In large firms, standardized numbering can reduce invoice reconciliation time by 30%.

Manual vs Automated PO Systems: Which is Better?

Managing purchase orders can be done manually or with software, but the choice impacts accuracy, efficiency, and control. Construction teams especially need clarity because multiple projects and suppliers are involved.

Managing PO Numbers in Excel

Many small projects or firms start with Excel or spreadsheets. It works because it’s simple, inexpensive, and easy to set up. You can:

- Track PO numbers sequentially

- Record dates, suppliers, and quantities

- Share files with a small team

But spreadsheets have limits. As projects grow, Excel struggles with:

- Human errors during data entry

- Missing updates across multiple users

- Limited reporting or audit-ready tracking

When Manual Systems Break Down

Manual PO systems start failing when volume increases. A few warning signs include:

- Volume thresholds: Hundreds of POs per month become hard to manage manually

- Error rates: Duplicate numbers, missing approvals, or misallocated costs

- Audit risk: Manual trails can be incomplete, making compliance difficult

Example: On a multi-site construction project, tracking 300 partial deliveries manually can lead to missed items or payment mistakes.

When to Use Procurement Software?

At a certain point, automated procurement tools make more sense than manual tracking. They offer:

- Integration with ERP, AP, and accounting systems

- Automatic numbering and version control

- Centralized audit trails

- Real-time visibility of spend and approvals

Whether it’s a high-volume multi-site project or smaller, long-running contracts, Pro Procurement ensures your POs work for you.

FAQs

What are PO approval thresholds and authorization rules?

Approval thresholds define who can approve purchases of certain amounts. Authorization rules set which roles can approve which type of purchase. For example, a project manager may approve POs up to $5,000, while anything above requires finance or senior management approval. This prevents unauthorized spending and ensures compliance.

How do POs support audit evidence and traceability?

Each PO acts as a record of approval, delivery, and payment. Audit trails show who requested, approved, and received materials. Properly numbered POs make it easy to trace every dollar and support internal or external audits.

How long should PO records be retained?

Retention policies depend on company rules and local regulations, but generally:

- Keep active POs for the duration of the project.

- Archive closed or cancelled POs for 5–7 years for audits and compliance.

How do internal controls improve compliance readiness?

Internal controls include approval workflows, PO matching rules, and system validations. They reduce errors, prevent fraud, and ensure every purchase follows company policies.

What is PO cycle time?

PO cycle time measures how long it takes to create, approve, and issue a PO. Shorter cycle times mean faster procurement and less project delay. Tracking this KPI identifies bottlenecks in approvals or supplier responsiveness.

What is the PO compliance rate?

This tracks the percentage of purchases made through approved POs versus off-system or manual purchases. High compliance indicates strong governance and reduces maverick spend.

What is Spend Under Management (SUM)?

SUM measures the portion of total company spending controlled via formal POs. Higher SUM gives better visibility into budgets, reduces overspending, and improves reporting.

What is the invoice exception rate?

This KPI shows the percentage of invoices that don’t match POs due to errors in quantity, price, or delivery. Lower exception rates mean the PO system is accurate, reducing disputes and late payments.

What is emergency or non-PO spend?

This refers to purchases made outside the approved PO system, often due to urgent needs. Tracking it helps identify gaps in the process and prevent uncontrolled spending.

How do PO numbers tie into KPIs?

PO numbers are the anchor for all these metrics: cycle time, compliance rate, SUM, and exception tracking. Without a structured numbering system, it’s impossible to measure procurement performance accurately or maintain compliance.

Conclusion

Even in 2026, PO numbers are far more than just a sequence of digits. They are the backbone of structured procurement, linking approvals, deliveries, invoices, and budgets. For construction firms juggling multiple projects, suppliers, and partial shipments, a properly managed PO system isn’t optional; it’s essential.

A well-structured PO number:

- Prevents duplicate or unauthorized purchases

- Provides a clear audit trail for compliance

- Enables accurate invoice matching and financial control

- Offers visibility into project budgets and spend

When POs are tied to a strategic procurement system, teams gain full control over spend. You can track expenses by project, enforce approvals, and prevent “maverick spend” before it happens. Structured procurement turns reactive problem-solving into proactive cost management, fewer surprises, fewer disputes, and smoother project execution.

How Pro Procurement Helps Construction Firms

Pro Procurement specializes in helping construction teams implement smarter PO systems tailored to their projects. With our tools and guidance, firms can:

- Standardize numbering across multiple sites and departments

- Automate approvals and version control

- Integrate POs with ERP, AP, and accounting systems

- Gain real-time visibility into spending and compliance