You already know that moment when a job you bid looks great on paper, and then a dozen small buys, one-off suppliers, and change orders eat the margin. Do you know what this is? It’s unmanaged spend.

This guide is for those who want to make bids, hit margin targets, and keep projects on time. We’ll cover what spend management is, why it matters in construction, the process you need to run it, the tech and metrics that make it measurable, and much more. Let’s start!

What is Spend Management?

Spend management is the system and discipline you use to control, analyze, and optimize all the money your business spends. Simply put, it is how a business keeps track of where its money goes and makes sure it’s spent the right way.

What is Business Spend Management (BSM)?

Business Spend Management (BSM) is the bigger, tech-based version of spend management. It uses software and data to connect purchasing, payments, and project teams, so no one is making decisions based on guesswork.

Why Spend Management Is Important in Procurement

Spend management isn’t about controlling people; it’s about controlling outcomes. In construction pro procurement, margins are thin, timelines are tight, and small leaks turn into big problems fast. When spend is managed properly, procurement stops reacting and starts steering.

● Financial Control & Budget Accuracy

When spend flows through approved contracts and POs, budgets stop being guesses. Procurement can see commitments early, flag overruns, and keep projects aligned with forecasts. That visibility prevents end-of-project surprises that blow margins.

● Improved Project Profitability

Managed spend means negotiated pricing is actually used. Fewer off-contract purchases. Less rework. Better buying decisions upfront. All of it adds directly to project profit, without cutting quality or speed.

● Reduced Risk & Stronger Compliance

Standard contracts, approval thresholds, and invoice matching reduce overbilling, duplicate payments, and scope creep. Compliance becomes built into the process instead of enforced after the damage is done.

● Better Supplier Performance & Accountability

When spend is visible, performance is measurable. Procurement can track pricing, delivery delays, quality issues, and change orders by supplier, and hold vendors accountable using real data.

● Faster Procurement Cycles and Fewer Delays

Clear catalogs, preferred suppliers, and streamlined approvals remove friction. Teams get what they need faster, without bypassing controls or creating chaos.

● Long-Term Cost Optimization

Over time, clean spend data reveals patterns. Procurement spots recurring waste, consolidates suppliers, and improves contracts. That’s how cost reduction becomes sustainable.

What Is Spend Under Management (SUM)?

Spend Under Management, or SUM, is the share of your total spend that flows through controlled channels:

- Approved contracts

- Purchase orders

- Catalogs

- Corporate buying cards with rules.

In simple words, SUM tells you how much of your money is visible and governed, and it matters because it correlates directly with fewer surprises, fewer disputes, and steadier margins.

Two Common Situations of SUM

- If SUM is low, you’ve got a lot of buying happening off the books, including site buys, last-minute vendors, or invoices that never matched a PO.

- If SUM is high, procurement processes are actually working, and your negotiated pricing and terms are sticking.

Want better visibility and control over your procurement spend? Talk to our experts and make every dollar count.

How to Calculate SUM?

It’s simple math. SUM is the percentage of total spend that’s managed. Here is a step-by-step example:

Pull your total spend for the period. Say it’s $1,000,000. And identify the portion that flowed through approved channels (contracts, POs, catalogs). Say that’s $600,000.

SUM = Managed Spend ÷ Total Spend. So 600,000 ÷ 1,000,000 = 0.6 → 60% SUM.

This 60% tells you two points:

- You’re seeing more than half of your spend.

- There’s a 40% blind spot to hunt down.

What to do?

Track the SUM monthly and aim to move it up; even small percentage gains translate into real dollars on projects.

What SUM Does?

Once spend is under management, procurement can influence outcomes. That’s where savings enter the picture. There are two types of savings:

Hard Savings

Hard savings come from spend that is already visible and controlled. You renegotiate pricing, enforce contract rates, or eliminate duplicate suppliers, and the invoice comes in lower. Simply put, hard savings is easy: it’s money you actually saved by spending less.

For example, you ordered 100 concrete forms at $100 each instead of $120. You saved $2,000, that’s hard cash in the project budget.

Cost Avoidance

Cost avoidance is different. It’s money you didn’t have to spend because procurement acted before the cost happened. The key is that this money never hits the books; you avoided it entirely.

For example, you locked in pricing on steel before the market spiked. If prices rose later, you didn’t have to pay the higher amount. Simply, you tightened change-order rules, so small scope changes didn’t automatically trigger expensive subcontractor work. Another example is you standardized specifications across projects, reducing the chance of mistakes that would require expensive rework or replacements.

Put simply:

- Hard savings = money saved on invoices;

- Cost avoidance = money you never had to spend because procurement controlled the risk ahead of time.

What is Total Cost of Ownership (TCO)

SUM tells you where you have control; savings tells you what changed; and TCO explains why procurement chose one option over another.

In construction, the lowest price often creates the most expensive outcome. Late deliveries delay labor, and poor quality materials trigger rework. Additionally, weak warranties increase maintenance and claims.

TCO forces procurement to look beyond price and account for:

- Installation time

- Reliability and defect risk

- Schedule impact

- Maintenance and replacement

- End-of-job disposal

When procurement uses TCO, it doesn’t just buy cheaper, howere, it buys smarter and protects project margins downstream.

The Best Spend Management Process

Managing spend isn’t a single step; it’s a journey. In construction, money flows across projects, suppliers, and equipment. Each stage can leak value if controls aren’t in place. That’s why procurement teams use the Source-to-Pay (S2P) lifecycle as the backbone of spend management.

What is Source-to-Pay (S2P)?

Consider S2P as a chain. If one link is weak, spend slips through, margins shrink, and project managers scramble. Spend management is the lens applied to the entire chain; it’s not one stage; it’s the rules and measurements that ensure every dollar is tracked and controlled.

Source-to-Pay (S2P) Lifecycle

S2P starts with finding the right suppliers and ends with making payment. Here’s the flow:

1. Strategic Sourcing

This is where the foundation is laid. Strategic sourcing groups spend into categories, run bids, and select suppliers based on total value. In construction, this means evaluating subcontractors for quality and schedule reliability, or locking in concrete and steel pricing to avoid market volatility.

Strategic sourcing also defines what will be managed. If procurement doesn’t actively decide which spend moves into contracts, POs, or catalogs, your SUM won’t grow, and you’ll be chasing uncontrolled spend instead of avoiding it.

2. Contract Lifecycle Management (CLM)

Once suppliers are chosen, contracts make those sourcing decisions enforceable. Standardized templates, clear change-order rules, escalation clauses, and delivery windows are critical. Every contract should be linked to a project code and supplier in your system because when POs and invoices reference contracts, you instantly increase visibility, enforce negotiated rates, and make audits simple.

3. Purchase Requisitions and Purchase Orders

Requisitions turn requests into formal orders, and POs turn orders into commitments. Discipline here captures spend under management. For construction, this means:

- Making POs mandatory for all materials above a threshold.

- Linking POs to contract numbers and project codes.

- Using approval thresholds that match the value and risk of the purchase.

Note: Without POs, you lose the traceability that allows procurement to enforce policies or claim savings.

4. Receiving & Invoice Matching

A PO isn’t enough; you need proof of receipt. Verification answers what was ordered and what has arrived, and in what condition. Field teams can use simple photo GRNs for materials; offices match invoices to POs and delivery notes. This three-way check avoids paying for missing or damaged items, one of the biggest sources of cost leakage on construction sites.

5. Payments and Financial Controls

Payments close the loop but also require safeguards. Segregation of duties, approval thresholds, and reconciliations ensure no rogue payments slip through. Spend management is only as strong as the controls at the payment stage: it’s the final gate that protects margins after sourcing, contracting, and ordering.

Where Spend Management Fits in S2P

Now the picture comes together: spend management isn’t a step in S2P, it’s the framework that overlays every step.

- Strategic sourcing defines managed spend

- Contracts enforce it

- POs capture it

- Receiving verifies it

- Payment closes it.

At each stage, SUM grows, visibility improves, and potential leaks are caught before they hit the books.

Key Challenges in Spend Management

● Maverick Spend in Construction Projects

Maverick spend happens when site teams buy outside approved suppliers or contracts. A project manager ordering emergency materials from a local vendor may keep work moving, but it bypasses negotiated rates. Over time, these quick fixes quietly reduce spend under management and inflate costs.

● Fragmented Supplier Base

Many contractors use multiple suppliers for the same materials, like 5 concrete vendors and 8 electrical suppliers. This fragmentation prevents volume leverage, complicates reporting, and makes standard pricing almost impossible to enforce.

● Poor Contract Adoption

Having contracts doesn’t ensure usage. When teams ignore preferred agreements, procurement loses control. For example, subcontractors billing outside agreed rates creates leakage that procurement can’t recover after the fact.

● Disconnected Systems & Manual Processes

ERP, AP, P-cards, and spreadsheets often operate separately. Manual approvals and rekeyed data increase errors and delay visibility, leaving procurement reactive instead of proactive.

● Inaccurate or Incomplete Spend Data

Missing project codes or inconsistent supplier names can hide thousands in spend. Dashboards look complete, but they aren’t telling the full story.

● Stakeholder Resistance & Low Compliance

If procurement processes feel slow or rigid, teams bypass them. Adoption improves only when controls support the job, not slow it down.

Category Management for Construction Spend

Different types of spend need different rules, even within the same S2P framework. By managing categories differently, procurement ensures every dollar, large or small, is visible and controlled. Here are the details:

- Materials: They are of high volume and critical to the schedule. Therefore, you should use catalogs, standardized specifications, and forward-buying for volatile items.

- Subcontractors: They are schedule-sensitive and high-impact. So, they can be managed by using pre-qualified pools, master service agreements, and performance tracking.

- Equipment: Balance hire and ownership costs with maintenance and downtime. You should include TCO in decisions.

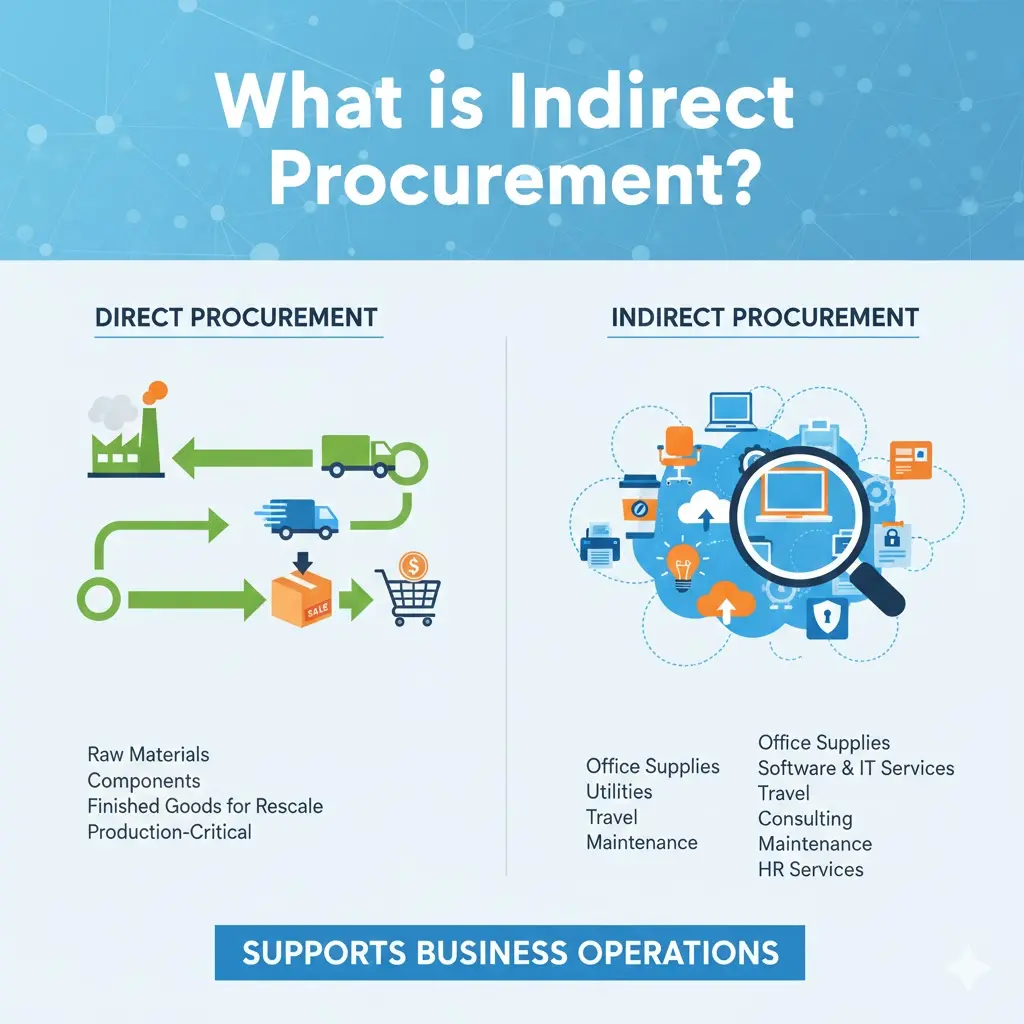

- Indirect & Operational Spend: Frequent, fragmented buys like PPE, office supplies, or small services. One can use controlled cards, punch-out catalogs, and preferred suppliers to reduce noise and improve visibility.

Spend Data Management as the Foundation of Visibility

Spend management only works if your data is clean, complete, and connected. In construction, money flows through dozens of POs, invoices, and suppliers. Without visibility, up to 30–40% of spend can be invisible, creating unexpected costs and inaccurate SUM reporting.

Key sources include

- ERP systems

- AP records

- POs

- Invoices

- P-cards.

Each captures different parts of spend, and together, they reveal the full picture.

How to Build a Winning Spend Management Strategy

Below is a practical, step-by-step playbook you can use.

1. Define Spend Management Objectives

Start with two or three concrete targets, like

- Increase spend management (SUM) by X percentage points.

- Cut maverick spend by Y dollars.

- Shorten the PO-to-payment cycle to Z days.

Pro Tip: Make each target tied to dollars or time. That keeps conversations practical.

2. Align Procurement with Finance & Project Teams

Procurement can’t operate in a silo. Finance validates baselines and savings; project teams enforce day-to-day compliance. Create a short RACI:

- Who owns SUM reporting?

- Who signs contracts?

- Who approves emergency buys?

Pro Tip: Hold a monthly 15-minute review with PMs and finance to review top unmanaged suppliers and immediate fixes.

3. Choose Between Centralized & Hybrid Procurement Models

Choose the model that matches your operations.

- Centralized: Procurement controls sourcing and contracts company-wide. Its is the best for volume leverage and standardization.

- Hybrid: Central team sets contracts and policies; local teams execute within guardrails. It is the best for fast-moving sites.

Pick the one, document how exceptions work, and who approves them, then enforce it.

4. Spend Policies & Approval Frameworks

Write simple, enforceable rules, including:

- PO thresholds

- Preferred supplier lists

- Emergency-buy process

- PO coding requirements.

Then, publish a one-page approval matrix and a one-minute mobile guide for site teams.

5. Governance Structure and Accountability

- Assign owners: category leads, data stewards, and a program sponsor (senior exec).

- Schedule quarterly audits of SUM, contract adoption, and unmatched invoices.

- Track KPIs publicly: SUM %, maverick $ amount, PO cycle time. Reward teams for improvements.

Note: Start small, measure fast, iterate. That’s how spend management becomes a repeatable advantage, and not a checkbox.

Technology & Tools for Spend Management

Technology is the thing that makes spend management repeatable. But tools alone won’t fix process problems. The right stack automates routine checks, enforces POs, ties contracts to invoices, and gives you the analytics to raise SUM with confidence.

Role of Technology in Modern Spend Management

Think of tech as three things: enforcement, visibility, and scale.

- Enforcement stops rogue buys (POs, approvals).

- Visibility shows who’s buying what, where, and at what price.

- Scale lets you apply those rules across dozens of projects without human bottlenecks.

Common Spend Management Tools

● eProcurement systems

These systems make catalogs and punch-outs available to field teams. They remove friction for common buys and push spend into controlled channels. Example: a site orders PPE from an approved catalog instead of buying ad hoc from a hardware store.

● Procure-to-Pay (P2P) Platforms

These platforms handle requisition, PO, receiving, invoice matching, and payment. Procure-to-Pay (P2P) is where three-way matching happens and where SUM grows measurably.

● Spend Analytics Tools

These are the tools that aggregate ERP, AP, and P-card data to show SUM, top unmanaged suppliers, and category trends. This is how you prioritize interventions.

● Contract Lifecycle Management (CLM) Systems

These systems store contracts, automate renewals, and link contract terms to POs and invoices. CLM makes negotiated rates enforceable and auditable.

The Role of ERP

If tools don’t integrate with your ERP and project-control systems, you’ll re-create silos. ERP integration must allow:

- Project codes and cost buckets to flow both ways.

- PO numbers to appear on invoices automatically.

- Contract IDs to tag transactions.

Without this, dashboards lie, and procurement loses credibility.

How to Select the Right Spend Management Platform?

Look for the following criteria:

- Integrations: ERP, AP, and project controls must be supported.

- Mobile usability: Field teams need to order and confirm receipts from phones.

- Category support: Can the tool handle subcontractor packages, not just SKUs?

- Automation level: Invoicing, three-way match, and exception handling.

- Adoption & training: Vendor offers quick onboarding and change support.

- Security & compliance: Data controls and audit trails.

- Total cost of ownership: Licenses + implementation + integrations + ongoing support.

Risk, Compliance, & Internal Controls

Risk controls are the safety net for spend management. They turn policy into protection by stopping duplicate payments, fraud, and regulatory headaches before they hit the P&L. In construction, where sums are large and timelines are tight, controls protect margins and reputations.

● Ensure Audit Trails &Transparency

Capture the who/what/when for every action: requisition, PO, GRN, invoice, approval, payment. When records are linked, audits are quick, and disputes are easy to resolve.

For example, a disputed subcontractor invoice is resolved in minutes when the original PO, approved change order, and delivery evidence are in one traceable thread.

● Segregate Duties

Separate who requests, who approves, and who pays. Don’t let one person create a vendor and authorize payment. For field realities, map roles to simple rules: site supervisor requests, project manager approves up to X, finance signs off above Y. This reduces both error and fraud risk without slowing work.

● Make & Implement Fraud Prevention and Payment Controls

Practical controls matter: three-way invoice matching, single-use virtual cards for ad-hoc buys, supplier-bank verification, and periodic supplier statement reconciliations. Watch for red flags, like sudden invoice pattern changes or multiple suppliers with similar bank details. Small automated checks catch most problems before they reach payroll.

● Consider Regulatory & Compliance Standards

Ensure contracts include required insurance, bonding, and tax/withholding clauses. Keep supplier documentation (licenses, W-9 equivalents) centrally stored and expiry-tracked. Regulatory lapses cost more than fines; they delay payments and projects.

FAQs

- How to measure procurement ROI simply?

ROI = (Total Benefits − Program Costs) ÷ Program Costs.

Include hard savings, cost avoidance (clearly labeled), and productivity gains; subtract licenses, integration, and implementation labor.

- How can you handle emergency buys without killing controls?

Pre-approved emergency vendor lists, single-use virtual card payments, post-purchase PO reconciliation within 48–72 hours, and mandatory justification logged to the project.

- How often should you audit SUM and related controls?

Quick operational audits weekly during rollout, monthly for project-level reviews, and quarterly enterprise audits covering contract adoption and vendor consolidation.

- How should change orders be controlled in CLM?

Require a documented change-order request, estimated cost impact, PM approval threshold, and contract amendment linked to the PO and invoice before payment.

- What’s the difference between spend management and expense management?

Spend management covers all organizational expenditures, including procurement and supplier contracts, while expense management focuses on employee reimbursements and small internal expenses.