You know that moment right before a house is handed over, dry paint, the floors are clean, but the place still feels like a shell? Then the sofa arrives, the lamps are set, and the fridge enters the kitchen. Suddenly, it’s not a shell anymore; it’s usable. That switch, from structure to space you can actually live or work in, is what FF&E does.

What is FF&E? It’s the furniture, fixtures, and equipment that make a space functional. Not the concrete or drywall, but the chairs, the built-in shelving, the coffee machines or the stuff people touch, use, and judge your project by. These items shape first impressions, operations, and long-term costs. In the commercial world, FF&E choices affect guest experience, employee productivity, and asset valuation.

Key Takeaways:

- FF&E stands for Furniture, Fixtures, and Equipment.

- It includes movable items (sofas, desks), semi-permanent items (lighting), and operational items (computers, appliances).

- FF&E is critical for budgeting, accounting (as a depreciable asset), and brand identity.

- FF&E Procurement is the process of sourcing, buying, and installing these items on time and within budget.

The Full Form & Meaning of FF&E

What is FF and E?

Let’s break that abbreviation down without the slang.

- Furniture: Movable items, including desks, sofas, conference tables, and shelving.

- Fixtures: Semi-permanent elements that often come with the fit-out, including lighting, cabinetry, and some built-in casework. Never mix structural items with them.

- Equipment: Operational kit, like appliances, AV, commercial kitchen equipment, medical devices, and IT racks.

Today, architects, interior designers, procurement teams, and contractors all use the term to specify, purchase, and track these non-structural assets.

The term grew out of accounting and hospitality/real-estate practices where it mattered to separate old, movable assets from the building. Back when hotel chains and commercial landlords started trading assets, they needed a smooth way to account for what moves with the tenant vs. what stays with the building, and FF&E was the answer.

What is FF&E in Construction?

After having an understanding of FF&E, let’s shift attention to what is FF&E in construction. To understand this concept better, imagine a house construction project.

You finish the framing, plumbing, electrical, and finishes. The contractor’s group cleans up. The structure, including walls, roof, and windows, is all done. But without appliances, bathroom vanities, kitchen cabinets, the bed and the sofa, the homeowner still can’t live there. That last mile, which is buying, delivering, and installing those items, is FF&E in construction.

Why It Matters

● Project Completion vs. Handover

Construction is done on the structure. FF&E is what turns completion into occupancy. Thoughtful FF & E scheduling ensures final delivery aligns with punchlist closure, so you hand the client a functioning home or commercial space on time.

● Schedule Smoothly

If FF&E is late, the whole handover slips. In other words, installers can’t work, inspectors are delayed, and turnover costs rise. Planning FF&E timelines reduces the risk of late handover. Recent industry reporting finds that supply-chain and procurement issues are a top cause of project delays; a significant share of contractors report supply-related delays affecting schedules.

● Operational Clarity for Contractors

Clear FF&E specifications remove guesswork. Instead of last-minute decisions, contractors get approved lists, POs, and delivery windows, which means fewer RFIs, fewer change orders, and excellent closeouts.

● Cost Control

FF&E typically sits in a distinct budget line. When you separate construction from FF&E early, you avoid budget overruns and get better pricing by consolidating orders or leveraging procurement expertise.

Other Benefits of FF&E

- Lifecycle cost analysis. Choose durable vs. cheap-for-now.

- Sustainability options, like FSC wood, low-VOC finishes.

- Tech-enabled items, like smart AV, built-in charging. They add value and reduce future operating costs.

Why FF&E is Essential for Design & Branding

Think of an office lobby. The architecture sets the tone, but FF&E sells the brand. The right reception desk, lighting, seating layout, and finishes tell a story, often before anyone says a word.

Why this Matters for Contractors & Owners

● Brand Consistency

FF&E choices for materials, finishes, and furniture style align the physical space with brand identity. For example, a tech startup’s office needs different FF&E than a law firm’s office.

● User Experience & Productivity

Ergonomic desks, acoustical partitions, and appropriate lighting directly affect worker comfort and output. Investing in FF&E reduces worker leaves and turnover over time.

● Revenue Implications

In retail and hospitality, FF&E influences guest spend and repeat visits. For example, hotels invest more in durable, brand-appropriate FF&E because guest experience drives RevPAR and reviews.

● Design Flexibility

Unlike structural elements, FF&E can be updated more often to match marketing cycles or seasonal changes. This means owners can keep spaces fresh without expensive renovations.

● Sustainability & Certification

Choosing certified materials and low-impact equipment supports LEED/ESG goals. It is a selling point for many institutional clients.

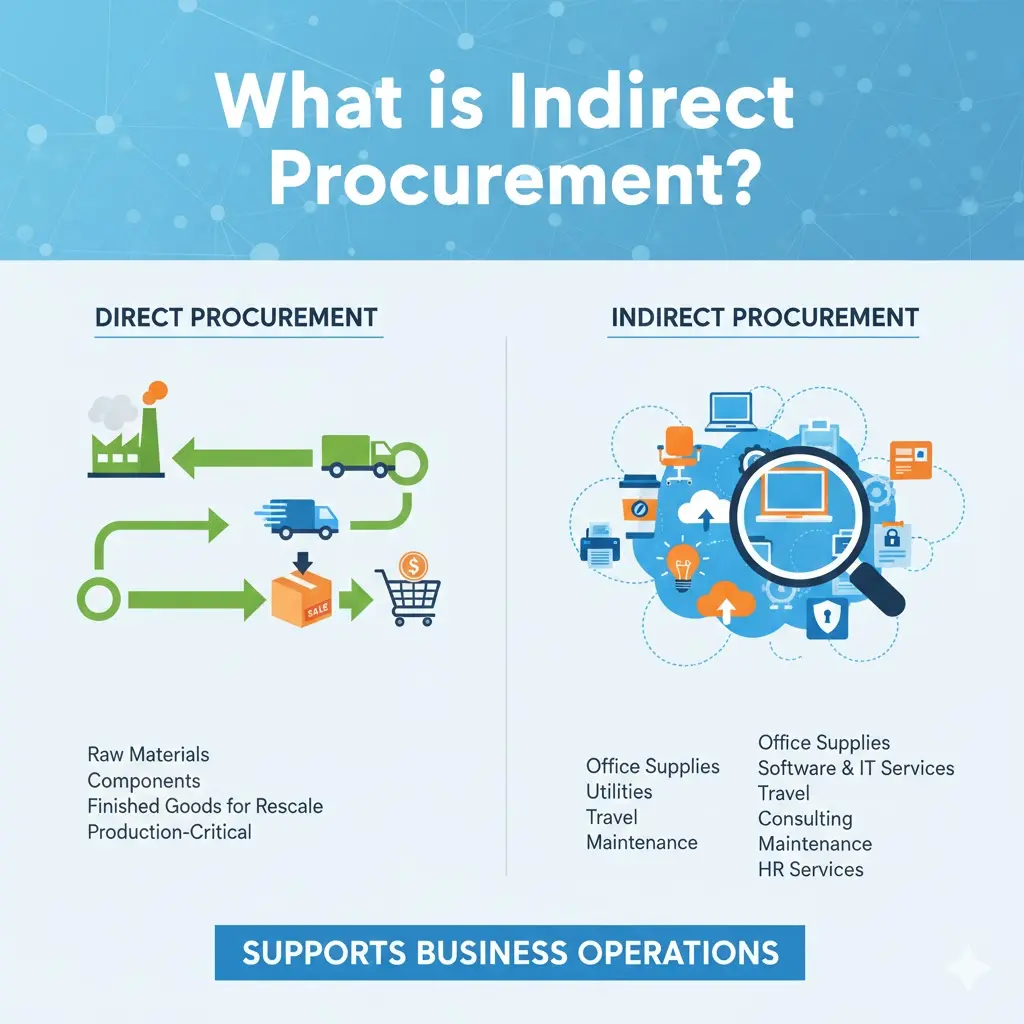

What is FF&E Procurement?

Before understanding FF&E procurement, let’s understand what procurement means. It is the end-to-end process of sourcing, contracting, buying, and managing goods and services, from identifying needs to delivery and payment.

In construction, procurement covers materials, trade services, long-lead equipment, and the administrative work that ensures the right products arrive when they’re needed.

FF&E procurement is the same thing, but focused on furniture, fixtures, and equipment. It includes:

- Writing specifications and furniture schedules

- Sourcing vendors

- Negotiating prices and lead times

- Placing purchase orders

- Tracking production and shipments

- Coordinating delivery and installation

- Ensuring quality and as-built documentation

It’s detail-heavy work. You’re juggling SKUs, manufacturer lead times, freight windows, installation team, and client sign-offs. Therefore, specialist FF&E procurement teams or software tools exist. They stop things from falling through the cracks and to meet the desired project schedule and budget.

Pro Tip: You can build a robust FF&E schedule and use tools that allow live updates and PO generation to keep everything transparent.

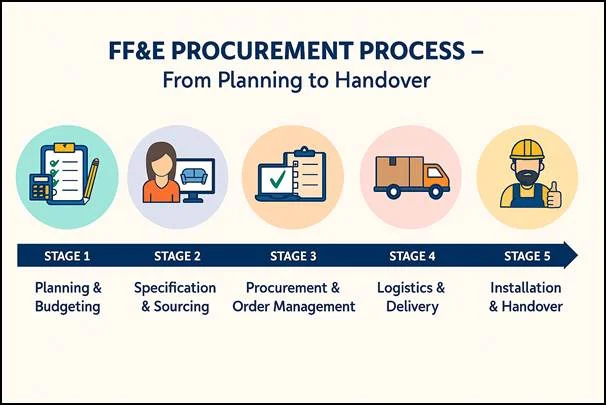

The Phases of FF&E Procurement

1. Planning & Budgeting

This phase involves 4 steps:

a. Define Requirements

Walk the space with the owner and interior designer. Create lists for each room (kitchen appliances, master bedroom case goods, living room seating). Include quantities, sizes, finishes, and performance requirements (e.g., commercial-grade refrigerator vs. residential).

b. Scope Elements

Decide what’s included in allowances vs. contractor-supplied items. For example, built-in cabinetry might be in the construction scope; freestanding furniture is FF&E. List this out in the contract.

c. Set the Budget

Use a bottom-up approach that itemizes likely costs, adds a contingency of 5–10% for FF&E lines, and sets approval thresholds. Consider lifecycle costs, like a cheap couch now might mean replacement in three years.

d. Choose the Methods for Defining Requirements

Deal with stakeholder workshops, moodboards, takeoffs from the design, and referencing product data sheets. Use historical project estimates to benchmark.

2. Specification & Sourcing

Move step-by-step, using the following points.

a. Select Suppliers

Consider past performance, lead times, warranty coverage, and capacity as primary filters. Ask for references on residential delivery reliability.

b. Compare Samples

Get physical samples where finish or comfort matters, including fabrics, veneer, and hardware. For equipment, request specific sheets, certifications, and test reports.

c. Best Option Logic

Balance cost vs. lead time vs. quality. For items with long lead times, choose a slightly higher-cost vendor if it keeps the schedule for decorative or less time-sensitive items, and price bid.

d. Ensure Quality

Request factory photos, QA checklists, and third-party certificates where relevant. Include acceptance criteria in POs to check damage thresholds and packaging standards.

Pro Tip: Use a product shortlist and approval log, which is a shared spreadsheet or FF&E platform. This will help you get the client’s sign-off before ordering.

3. Procurement & Order Management

Now, turn approvals into orders.

a. Understand What POs Are?

Purchase Orders are legal documents that confirm the item, quantity, price, delivery date, and terms. They’re the handshake you convert to contractual authority.

b. Manage POs

Keep a live register with PO number, vendor acknowledgment, production start, ship date, ETA, and installation window. Escalate gaps immediately.

c. Payments & Milestones

Next come payments. 30% deposit, 60% production, 10% on delivery/inspection, but this can vary. Make sure retainage and warranty terms are transparent.

d. Supplier Coordination Methods

Include weekly PO status calls, milestone checklists, and cross-checking shipping docs. Use centralized communication via procurement software to avoid lost emails. Popular software can auto-generate POs from an FF&E schedule and track acknowledgments.

4. Logistics & Delivery

This is where many projects trip.

a. Transport & Staging

Organize carriers that handle residential deliveries and inside placements. For oversized or delicate items, choose white-glove delivery.

b. Storage & Residues

If items arrive before site readiness, arrange secure off-site storage or covered on-site staging. Track inventory and inspect on arrival for damages.

c. Timely Delivery Stats

Supply-chain disruptions remain a top cause of delay in construction; many firms report project impacts from supply issues. Planning and multiple sourcing mitigate the risk.

5. Installation & Handover

The last mile matters.

a. Final Setup

Installation teams assemble furniture, secure fixtures, run AV/IT, and connect equipment. Have an installation checklist and a snagging/punchlist app to track issues.

b. Inspection

Technical checks (appliance commissioning, AV calibration), cosmetic checks (scratches, finish matches), and client walkthrough for approval.

c. Client approval & documentation

Collect warranties, maintenance manuals, and as-built FF&E schedules. Final payment is often linked to the client’s sign-off.

The Importance of Logistics in FF&E Projects

Logistics is what wins or loses projects. It is actually the invisible schedule driver. You can specify the perfect sofa, but if it’s stuck at a port, you can’t install it. Delays in transport, customs, or last-mile delivery directly push back handover dates and inflate temporary storage costs.

Common Logistics Failure Points You Must Know

- Lead-time mismatch or ordering too late

- Poor carrier selection, like no white-glove service for delicate items

- Inadequate staging plans, such as no secure storage

- Lack of tracking and escalation procedures

A large share of contractors report supply-chain-related schedule impacts; project-control studies show supply issues are among the top causes of delay and cost overruns across construction sectors. That’s why procurement teams treat logistics as a high-risk path and build mitigation: multiple suppliers, early POs, & pre-booked carriers.

Who Oversees FF&E Procurement in a Project?

Different people take the lead depending on project size. Here are typical roles:

● Interior Designer

Designers write FF&E specifications and approve aesthetics. They drive product selection and client sign-off, but usually don’t manage purchase orders or logistics on larger projects.

● Procurement Managers & FF&E Buyers

The procurement lead handles POs, vendor contracts, negotiating lead times, and payment terms. They’re the operational owner, coordinating production and delivery.

● Construction Project Managers

Oversees integration of FF&E into the construction schedule, sequencing deliveries, staging on site, coordinating installers, and ensuring handover timelines are met.

● General Contractors & Sub-Contractors

GCs manage on-site logistics, protect delivered items, and coordinate installation windows with trades. They’re accountable for site readiness and final acceptance of installations.

● Logistics Coordinators & Installers

They handle last-mile delivery, installation, and conduct on-site quality checks. For large projects, a dedicated logistics coordinator ensures scheduling and carrier communication are on point.

Common FF&E Procurement Challenges & How to Avoid Them

● Project Delays

Delays often come from long lead times, late approvals, or shipping bottlenecks. Avoid by locking long-lead items early, requiring vendor acknowledgments, and building realistic installation windows. Contingency buffers, like time and budget, and multiple sourcing, reduce schedule risk.

● Quality Inconsistencies

Samples that don’t match the delivered product are common. Mitigate by getting physical samples, including strict acceptance criteria in POs, and holding final payments until inspection passes. Use vendors with proven QA processes and documented warranties.

● Cost Overruns

Scope creep, last-minute changes, and freight surprises inflate costs. Fix this with detailed FF&E schedules, line-item budgets, firm POs, and transparent change-order procedures. Track spend against budget in a live register.

● Miscommunication

Multiple stakeholders, including designers, procurement experts, GC, and others, create handoff failures. Use centralized tools, regular status meetings, and a single source of truth for the FF&E schedule to keep everyone aligned. Clear approval steps prevent surprises.

Why Choose a Professional FF&E Procurement Partner?

Ask yourself: do you want to spend the last month of a project firefighting missing appliances, late sofas, and broken fixtures, or hand the client keys on schedule? A pro FF&E partner knows the answer.

So, What is FF&E? It’s the set of items that turn a building into a usable space, and sourcing those items well takes time and experience. Pros bring vendor networks, negotiated terms, and process discipline. They standardize specifications, run QA, coordinate logistics, and keep a single master schedule.

Ultimately, you experience fewer RFIs, fewer change orders, and reduced on-site issues. A professional partner also reduces financial risk by managing deposits, retention, insurance, and warranty handovers. For contractors struggling with trades and supply issues, this is the difference between a stressed closeout and a smooth one that gets you paid faster and keeps clients satisfied.

Final Words

So, What is FF&E? It’s the furniture, fixtures, and equipment that transform completed construction into usable, branded, revenue-producing space. FF&E matters because it finishes the job, and it’s often the make-or-break element for schedule, client satisfaction, and lifecycle costs.

If you want to avoid last-minute headaches, missed deadlines, and warranty issues, bring procurement in early. A focused FF&E procurement partner protects your schedule and margin so you can close projects professionally.

If you’d like help turning your next project’s FF&E schedule into a guaranteed handover, check out Pro Procurement. We specialize in FF&E sourcing, vendor management, logistics, and installation coordination for contractors and builders. Learn how we can take the FF&E risk off your plate at https://proprocurement.us/!

FAQs

What does FF&E include?

FF&E includes movable furniture (sofas, desks), fixtures (lighting, cabinetry), and equipment (appliances, AV, IT). Items are non-structural and often depreciate separately for accounting purposes.

What is the difference between FF&E and OS&E?

FF&E covers furniture, fixtures, and equipment. OS&E (Operating Supplies & Equipment) usually refers to consumables and small operating items (linens, kitchen utensils, smallwares) used in hospitality and food service.

What is FF&E in construction projects?

In construction, FF&E are the non-structural items procured and installed after core construction is complete. They are the finishing elements that make spaces usable and branded. Proper FF&E procurement links purchases, logistics, and installation with the construction schedule to ensure smooth handover.

Why is FF&E procurement important?

FF&E procurement ensures the right products are specified, ordered, delivered, and installed on time and on budget. It mitigates schedule risk, controls costs, and protects the design intent and warranty responsibilities. Good procurement prevents last-minute problems that delay occupancy.

Who handles FF&E procurement?

Typically, a combination of interior designers, procurement managers or FF&E buyers, project managers, and logistics coordinators. For complex projects, a dedicated FF&E procurement firm may run the whole process.