Procurement has changed a lot in the past few years. Between 2020 and 2026, supply chain disruptions became much more common. Some industries saw lead times triple, and costs go up by as much as 25% during the pandemic. These problems revealed how easily supply chains can break down and how fast costs can rise. The old way of buying furniture, fixtures, and equipment no longer works. In 2026, using strategic sourcing is essential for success.

FF&E procurement now involves more risk. Lead times are longer, specifications are stricter, and the market is less predictable. A late delivery or incorrect equipment can hold up an entire project. For example, if custom furniture arrives late, contractors may have to wait, tasks get rescheduled, and overhead costs go up. This can reduce the project’s return on investment and affect both finances and client satisfaction.

Reactive sourcing often involves hidden costs such as expedited shipping fees, temporary solutions, and strained supplier relationships. In these situations, AI insights, local supply options, and a focus on sustainability are key to staying on track. This guide explains what strategic sourcing means in 2026, how it is different from traditional procurement, and why FF&E specialists need to use a modern, data-driven approach.

Strategic Sourcing vs. Traditional Sourcing

Understanding the difference is key. Traditional procurement is transaction-based, while strategic sourcing is more thoughtful, analytical, and value-focused. In FF&E, every purchase affects design, schedules, and project outcomes, so this distinction is important.

For example, one company chose the lowest bid for custom office furniture, but the products arrived with defects, causing delays and unhappy clients. Another company partnered with a reliable supplier, paid a bit more upfront, and received better service, on-time deliveries, and long-term savings. This shows why strategic sourcing is crucial for FF&E procurement in 2026.

Here’s a clear comparison for 2026:

| Features | Traditional Sourcing | Strategic Sourcing 2026 |

| Objective | Lowest cost per item | Total value over lifecycle (cost + quality + delivery) |

| Approach | Reactive, ad hoc | Proactive, data-driven, aligned with project goals |

| Supplier Relationships | Transactional, short-term | Collaborative, long-term, performance-focused |

| Data Utilization | Minimal, manual spreadsheets | AI-assisted analytics, predictive insights |

| Risk Management | Limited to obvious disruptions | Scenario modeling, multi-sourcing, and regional resilience |

| Sustainability / ESG | Often overlooked | Integrated into decision-making (Scope 3, circular economy) |

| Flexibility / Adaptation | Hard to pivot | Agile, scenario-based adjustments for changing demands |

| FF&E-Specific Impacts | Delays, specification mismatches, and cost overruns | Optimized lead times, accurate specification matching, and lifecycle cost efficiency |

Why this matters:

- Traditional sourcing might work in a stable environment, but 2026 isn’t stable.

- FF&E procurement errors are highly visible; delayed chairs or misaligned fixtures can derail a room or project.

- Strategic sourcing anticipates issues before they hit, using data, AI, and supplier intelligence to stay ahead.

Why Strategic Sourcing is Essential for 2026

The time when you could just place an order and hope everything worked out is gone. In FF&E procurement, even small errors can lead to major issues. Delays, mismatched fixtures, or equipment that doesn’t meet needs can disrupt whole projects. In 2026, strategic sourcing isn’t just a better choice; it’s necessary to stay efficient, profitable, and competitive. Here’s why:

● Supply Chain Disruptions As A New Normal

Global events, political changes, and shipping delays have made FF&E suppliers less reliable than before. Lead times can stretch from weeks to months, and last-minute changes can throw off project schedules.

With strategic sourcing:

- Multiple vetted suppliers are identified in advance.

- Alternative sourcing routes are planned regionally.

- Predictive analytics forecast shortages before they hit

Think about ordering a custom set of office chairs. With traditional procurement, you wait until you need to order. Strategic sourcing, on the other hand, spots possible delays early, so you have backup suppliers and less risk.

● Inflation and Cost Volatility Impact On Projects Directly

Prices for furniture, fixtures, and equipment can change a lot. Even a 5% increase during a large purchase can push budgets over the limit.

Strategic sourcing addresses this by:

- Evaluating total lifecycle costs rather than unit price

- Locking in longer-term contracts at predictable rates

- Prioritizing suppliers who provide transparency and value

This approach isn’t about paying less upfront; it’s about avoiding expensive surprises down the line.

● ESG and Scope 3 Requirements Importance

Sustainability is important for both compliance and reputation. Many organizations now track Scope 3 emissions, which cover the impact of their suppliers. Buying FF&E can add a lot to these emissions because of the materials, manufacturing, and shipping involved.

Strategic sourcing in 2026 ensures:

- Supplier sustainability credentials are assessed.

- Materials are ethically sourced and environmentally compliant.

- Circular economy practices are prioritized, including recyclable or reusable fixtures and modular furniture.

Ignoring these risks, fines, brand damage, and future-proofing your supply chain.

● Importance Of ROI and Value Creation

Traditional sourcing measures success by unit cost. Strategic sourcing evaluates total value:

- Delivery reliability

- Quality and specification compliance

- Supplier collaboration and innovation

In FF&E projects, delays or quality problems are more than just inconvenient; they are noticeable and expensive. When procurement is high-quality and on time, it helps keep the project on schedule, makes clients happier, and delivers clear returns on investment.

● FF&E Procurement Complexity & Modern Tools

Furniture, fixtures, and equipment are not one-size-fits-all products. Orders are often customized, involve several parts, and may come from different vendors, which increases the risk and cost of mistakes.

Strategic sourcing leverages:

- AI-driven spend analysis

- Vendor scorecards and risk assessment

- Automated alerts for specification mismatches

The result comes in the form of fewer errors, faster approvals, and a smoother process from design to delivery.

Key Takeaway

In 2026, FF&E procurement can’t rely on luck or tradition. Strategic sourcing makes your process:

- Predictable

- Cost-efficient

- Resilient

- Sustainable

It’s the difference between a smooth project and a last-minute scramble that costs money, time, and reputation.

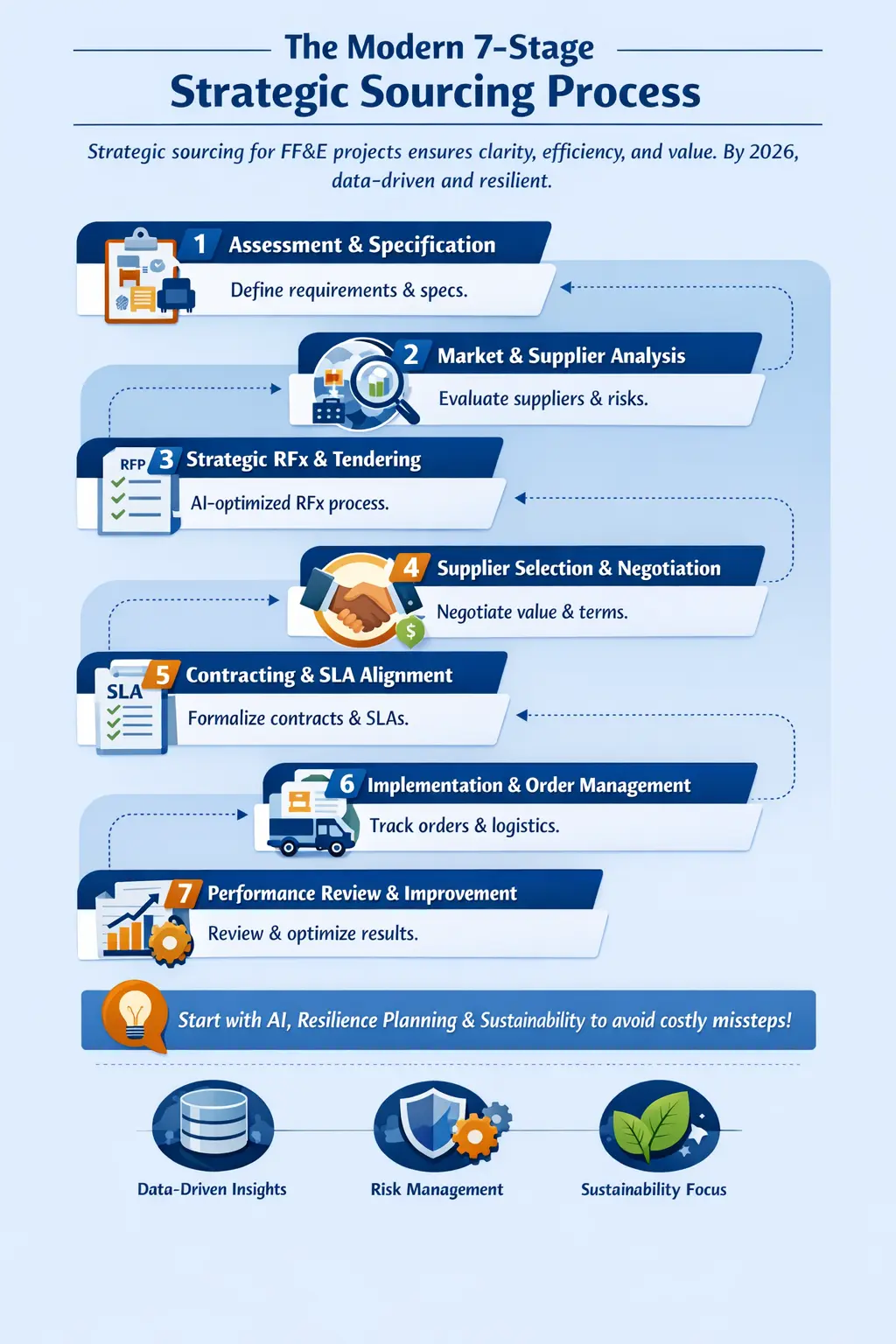

The Modern 7-Stage Strategic Sourcing Process

Strategic sourcing is not just one decision. It is a process that shapes every step of procurement, which is especially important for FF&E projects with strict timelines, detailed specifications, and tight budgets. By 2026, this process will rely on data, be built to handle challenges, and aim to deliver value.

Here’s the 7-stage framework:

Stage 1: Assessment & Specification

Before buying anything, you need clarity on what exactly is required. For FF&E, this includes:

- Furniture types, sizes, and finishes

- Equipment specifications, compatibility, and certifications

- Delivery timelines and installation requirements

Why it matters:

When specifications are unclear, projects can face delays, mismatched parts, and higher costs. By using strategic sourcing, you set clear needs from the start, which helps avoid unexpected issues. AI tools can also review past procurement data to improve your specifications and order amounts.

Stage 2: Market & Supplier Analysis

Not all suppliers are created equal. Strategic sourcing involves:

- Mapping global and regional suppliers

- Evaluating lead times, production capacity, and reliability

- Analyzing risk factors, including political, financial, and logistical

For FF&E, supplier analysis often identifies who can handle custom orders, sustainable materials, and bulk shipments efficiently.

Stage 3: Strategic RFx & Tendering

Requesting information, proposals, or quotations, including RFI, RFP, and RFQ, is more than paperwork. Modern strategic sourcing ensures:

- Templates are AI-optimized for clarity and compliance.

- RFx includes sustainability, lifecycle cost, and quality metrics.

- Bids are scored objectively against predefined criteria.

The goal is a fair, transparent evaluation that balances cost, quality, and reliability.

Stage 4: Supplier Selection & Negotiation

Selection isn’t just about the lowest price. In 2026, the focus is on:

- Lifecycle value

- Supplier collaboration and innovation

- Flexibility to adjust to market fluctuations

Negotiation strategies for FF&E:

- Bundle items for discounts

- Lock in delivery schedules.

- Include sustainability and warranty clauses.

Stage 5: Contracting & SLA Alignment

Contracts formalize expectations. Strategic sourcing ensures:

- Clear Service Level Agreements (SLAs)

- Defined penalties for delays or quality issues

- Sustainability and Scope 3 requirements embedded

For FF&E projects, contracts often cover custom manufacturing tolerances, modularity, and installation support.

Stage 6: Implementation & Order Management

Execution is where planning meets reality:

- Orders are placed and tracked in real-time.

- AI tools predict potential delays or bottlenecks.

- Inventory and logistics are coordinated for smooth delivery.

For FF&E, the implementation process covers onsite installation schedules, assembly, and handover steps. These are tracked digitally to keep disruptions to a minimum.

Stage 7: Performance Review & Continuous Improvement

After delivery, the process isn’t over. Continuous improvement ensures future sourcing is smarter:

- Assess supplier performance

- Track cost savings and compliance metrics

- Adjust specifications and sourcing strategies based on lessons learned.

This stage closes the loop, ensuring your next FF&E procurement cycle is faster, cheaper, and less risky.

Pro Tip:

A small misalignment at any stage can lead to project delays or extra costs. For this reason, it is essential to include AI, resilience planning, and sustainability from the very beginning in 2026.

For a deeper understanding of how modern strategic sourcing integrates technology and AI, check out our article on AI in procurement.

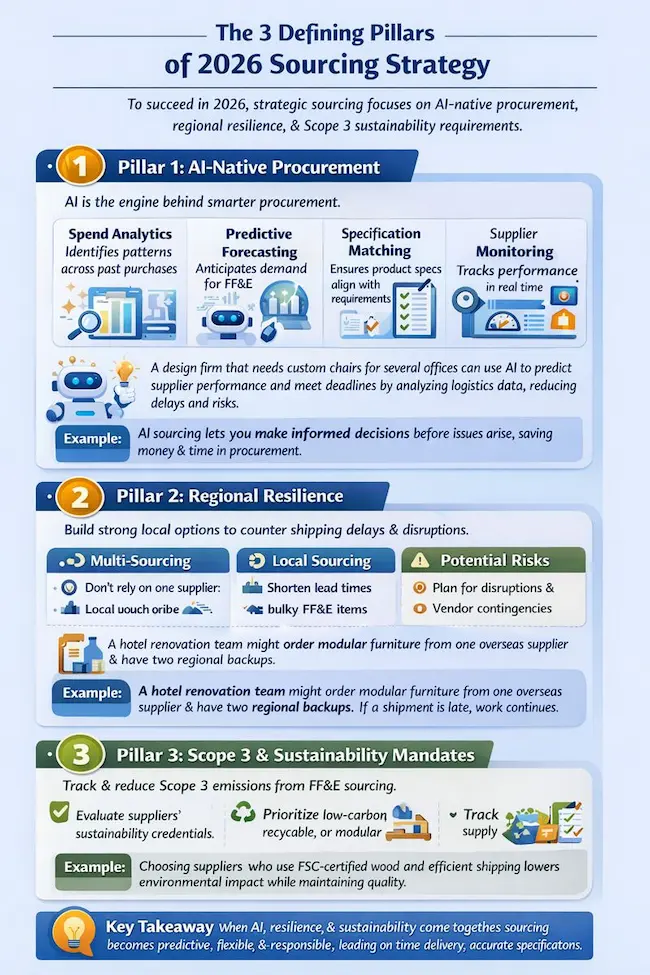

The 3 Defining Pillars of 2026 Sourcing Strategy

Strategic sourcing is more than following a 7-step process. To succeed in 2026, organizations should focus on three main areas: AI-native procurement, regional resilience, and Scope 3 and sustainability requirements. These pillars guide decisions, improve efficiency, and help manage risk, especially in FF&E procurement, where lead times, customization, and supplier complexity can be challenging.

Pillar 1: AI-Native Procurement

AI isn’t a luxury anymore; it’s the engine behind smarter procurement.

How AI transforms FF&E sourcing:

- Spend Analytics: Identifies patterns across past purchases to optimize future orders.

- Predictive Forecasting: Anticipates demand for furniture, fixtures, and equipment before orders are needed

- Specification Matching: Ensures product specs align with project requirements, reducing rework or returns

- Supplier Performance Monitoring: Real-time tracking flags potential delays, quality issues, or risk exposure

Example:

A design firm that needs custom chairs for several offices can use AI to predict which supplier is most likely to meet deadlines by looking at past performance and logistics data. This helps reduce delays, lower risks, and gives the firm better leverage in negotiations.

Why does it matter in 2026?

AI-native sourcing uses data to give you insights early, so you can make decisions before issues come up. In FF&E procurement, this helps you save both money and time.

Pillar 2: Regional Resilience

Global supply chains are vulnerable. Shipping delays, tariffs, and world events can disrupt even the most careful plans. Building regional resilience means adding backup options and staying flexible in your sourcing approach.

Key strategies:

- Multi-sourcing: Don’t rely on a single supplier; identify regional alternatives

- Local sourcing options: Reduce lead times and shipping costs, especially for bulky FF&E items

- Potential risks: Plan for disruptions, including storage, logistics, and vendor contingencies

Example:

In a hotel renovation, a team might order modular furniture from one main overseas supplier and have two regional backups. If a shipment is late, work can keep going without expensive delays.

Why does it matter in 2026?

Resilience is more than just insurance. It gives you an edge over competitors. Projects finish on time, costs stay in check, and clients feel more confident.

Pillar 3: Scope 3 & Sustainability Mandates

Sustainability is now tracked, regulated, and expected by clients. Scope 3 emissions, which are the indirect emissions from suppliers’ activities, are a key focus. FF&E procurement can play a big role, from sourcing raw materials to managing logistics.

Actionable steps for 2026 sourcing:

- Evaluate supplier sustainability credentials before onboarding.

- Prioritize low-carbon, recyclable, or modular materials.

- Track Scope 3 emissions for each procurement decision

- Include ESG criteria in RFx and contracts.

Example:

Choosing office furniture from suppliers who use FSC-certified wood, water-based finishes, and efficient shipping helps lower environmental impact without sacrificing quality or style.

Why does it matter in 2026?

Clients, regulators, and investors are holding projects to higher standards. Making sustainability part of FF&E sourcing is now necessary to protect your reputation and stay compliant.

Key Takeaway

When AI, resilience, and sustainability come together, strategic sourcing becomes more predictive, flexible, and responsible. For FF&E procurement, this leads to on-time delivery, accurate specifications, cost savings, and less environmental impact. These factors are all key to project success in 2026.

earn more about building efficient and resilient supply chains in our article on end-to-end procurement.

Discover how to optimize your FF&E sourcing. Read our full guide on building efficient, resilient, and sustainable supply chains.

Conclusion

In 2026, procurement will move beyond simply reacting or focusing on the lowest price. The focus will be on strategic, data-driven, resilient, and sustainable sourcing. This is especially important for FF&E, where delays, mismatched specifications, or quality problems can affect the whole project.

By now, you’ve seen that strategic sourcing in 2026 is built on three pillars:

- AI-Native Procurement, turning data into foresight, improving accuracy, reducing waste, and optimizing vendor selection.

- Regional Resilience, mitigating disruptions with multi-sourcing, local alternatives, and contingency planning.

- Scope 3 & Sustainability Mandates, aligning sourcing decisions with ESG goals, regulatory compliance, and long-term project value.

Coupled with the 7-stage sourcing process, these pillars give you a roadmap to reduce project delays, optimize FF&E lifecycle costs, improve supplier performance, and ensure compliance and sustainability. So, strategic sourcing in 2026 is not just a tool or a report. It is a complete approach that turns procurement from a routine task into a competitive advantage.

Connect with Our Specialists for a 2026 Procurement Audit!

Prepare your sourcing strategy now, before the next supply chain disruption occurs.

Our team can help you:

- Review your current FF&E procurement process.

- Find areas to improve in AI use, supplier reliability, and meeting sustainability standards.

- Get practical advice and a plan tailored to your needs for 2026.

Begin building a smarter, faster, and more reliable sourcing process. Contact our specialists today.

FAQs

What is the main difference between Strategic Sourcing and Traditional Procurement in 2026?

Strategic sourcing is proactive, value-driven, and data-backed. Traditional procurement focuses mainly on transactional cost savings. For FF&E, strategic sourcing ensures timely delivery, specification compliance, and lifecycle value.

How does AI improve the Strategic Sourcing ROI?

AI enables predictive analytics, spend optimization, supplier performance monitoring, and risk forecasting, reducing delays, errors, and unnecessary costs.

Why is Regional Resilience a priority in the 2026 roadmap?

It mitigates supply chain disruptions, reduces lead times, and ensures project continuity by using multi-sourcing and local suppliers.

What are Scope 3 Mandates, and why do they matter for sourcing?

Scope 3 emissions cover indirect supplier-related environmental impact. For FF&E procurement, tracking and reducing these emissions ensures sustainability compliance and meets client and regulatory expectations.

How often should we conduct a Strategic Sourcing Audit?

Ideally, at least annually, or whenever project volumes, supplier markets, or sustainability mandates change. Frequent audits allow you to identify gaps and continuously improve sourcing effectiveness.