As a contractor, you must have run projects, fixing crises while knowing who is leaving the right track and disturbing the whole procurement process. But sometimes, everything looks fine on paper: no broken materials and no waste, still, there is something that increases the cost. What is this? This is actually hidden spending that indirect procurement deals with.

Most construction teams obsess over materials, labor, and subcontractors. They are all direct spend, which is visible and easy to point to. On the other hand, indirect spending is the stuff running in the background. For example, software renewals, equipment servicing, temporary labor, safety supplies, consultants, office leases, utilities, staff training, IT tools, etc., are all indirect expenses.

Individually, these costs look harmless. Together, they can swallow 30–50% of the total organizational spend in some construction and engineering firms. In other words, Indirect procurement is often the fastest way to unlock savings without slowing projects down. Manage it well, and your margins change faster than if you fought price battles on concrete.

If you want to know more about indirect procurement, continue reading The Strategic Guide to Indirect Procurement for Construction Buyers!

What is Indirect Procurement?

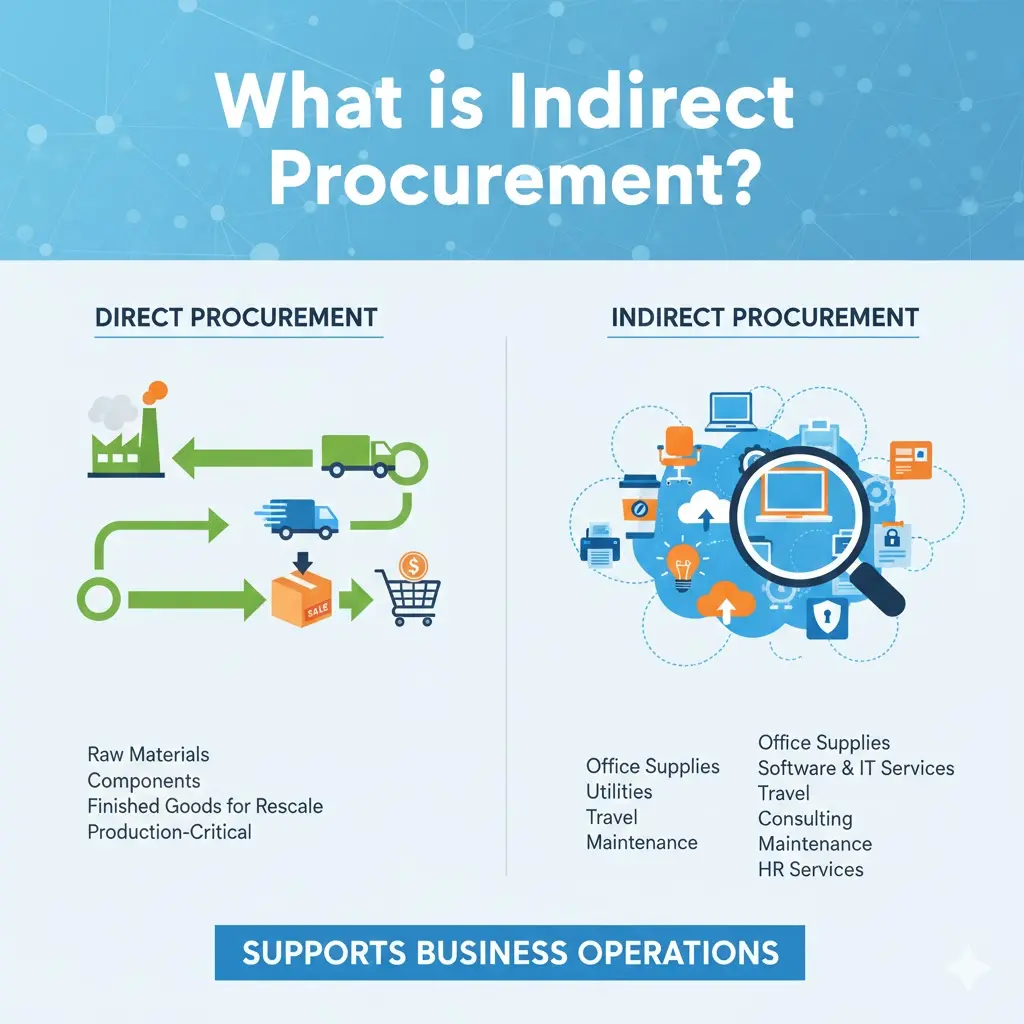

Indirect procurement is the process of sourcing, managing, and paying for goods and services that support your business, but don’t directly become part of what you build. For better understanding, you can consider it as:

- Direct procurement builds the project.

- Indirect procurement keeps the business running so the project can exist.

Here’s what indirect purchasing covers:

- IT systems and software

- Professional services

- Equipment maintenance

- Facilities and utilities

- Temporary staffing

- Safety and compliance services

- Insurance, legal, and finance support

Why Indirect Procurement Matters?

We have left the old methods of construction. Today, building projects are more complex, margins are tighter, local building regulations have changed, and technology is advancing day by day. At the same time, project owners demand predictable estimates, meaningful audits, fewer or no financial surprises, and better supplier accountability. Do you know how you can achieve all these goals? Indirect procurement.

With this, you can reduce uncontrolled spending, improve operational uptime, standardize supplier performance, strengthen compliance, and free up project teams to focus on building. In other words, indirect procurement helps you avoid under- or over-buying, duplicate vendors, bloated contracts, shadow IT, and endless invoice disputes.

To control maverick spend, supplier sprawl, and hidden costs, it’s essential to understand tail spend in procurement, which is exactly what indirect procurement is designed to fix:

Direct vs. Indirect Procurement

Imagine two systems:

- One is the crane and concrete.

- The other is the site radio, the rented scissor lift, the last-minute the weekly sanitation truck.

Direct procurement focuses on product, timing, and logistics. Indirect procurement is about people, uptime, and productivity.

The tactics are different: Direct benefits from hedging and bulk buys, indirect wins from governance, guided buying, and supplier consolidation.

| Area | Direct Procurement | Indirect Procurement |

| Purpose | Build the product | Run the business |

| Examples | Concrete, steel, lumber | Software, MRO, services |

| Spend Visibility | High | Often fragmented |

| Supplier Volume | Fewer, high-value | Many, low-to-mid value |

| Ownership | Project teams | Operations/finance |

| Risk | Supply delays | Cost leakage, non-compliance |

| Success Metric | On-time delivery | Efficiency & control |

Simply put, direct procurement is about materials and output; however, indirect procurement is about people and productivity. If direct spend fails, a project stalls; On the other hand, if indirect spend fails, teams burn out, systems break, and costs spiral quietly.

The Indirect Procurement Categories that Actually Matter on the Site

If you manage sites, these are the categories that will keep costing you unless you own them:

1. IT and SaaS Tools

Technology spend has exploded in construction, not just ERP systems, but everything around them, including

- Project management platforms

- Estimating software

- Cybersecurity tools

- Cloud storage

- Collaboration tools

- License renewals nobody tracks

If you leave them unmanaged, IT expenses duplicate quickly. Regarding playbook, for IT & SaaS, consolidate licenses and negotiate enterprise terms or seat true-ups to avoid duplicative subscriptions. Don’t forget data-security clauses as project files are critical.

2. Professional Services

These aren’t one-off costs anymore and often renew quietly. They include:

- Legal counsel

- Marketing agencies

- HR consultants

- Accounting services

- Compliance advisors

3. MRO: Maintenance, Repair, & Operations

This one hits on-site operations directly as they include:

- Equipment servicing

- Replacement parts

- Tools

- Safety gear

- Emergency repairs

Simply put, MRO spend keeps sites running, and their poor control means increasing downtime as well as significant safety risks. For playbooks, MRO and tools benefit from kitting and weekly replenishment. You should create trade-specific kits (carpentry, MEP) to reduce downtime and ad-hoc buys.

4. Facilities & Operational Essentials

They get extremely expensive over time if not managed well, including:

- Office leases

- Utilities

- Waste management

- Cleaning services

- Security

Remember that these contracts are long-term, and small inefficiencies in them always lead to significant loss.

The Modern Indirect Procurement Process

You don’t need a PhD in procurement to make a good process. You need a repeatable flow that site teams actually use.

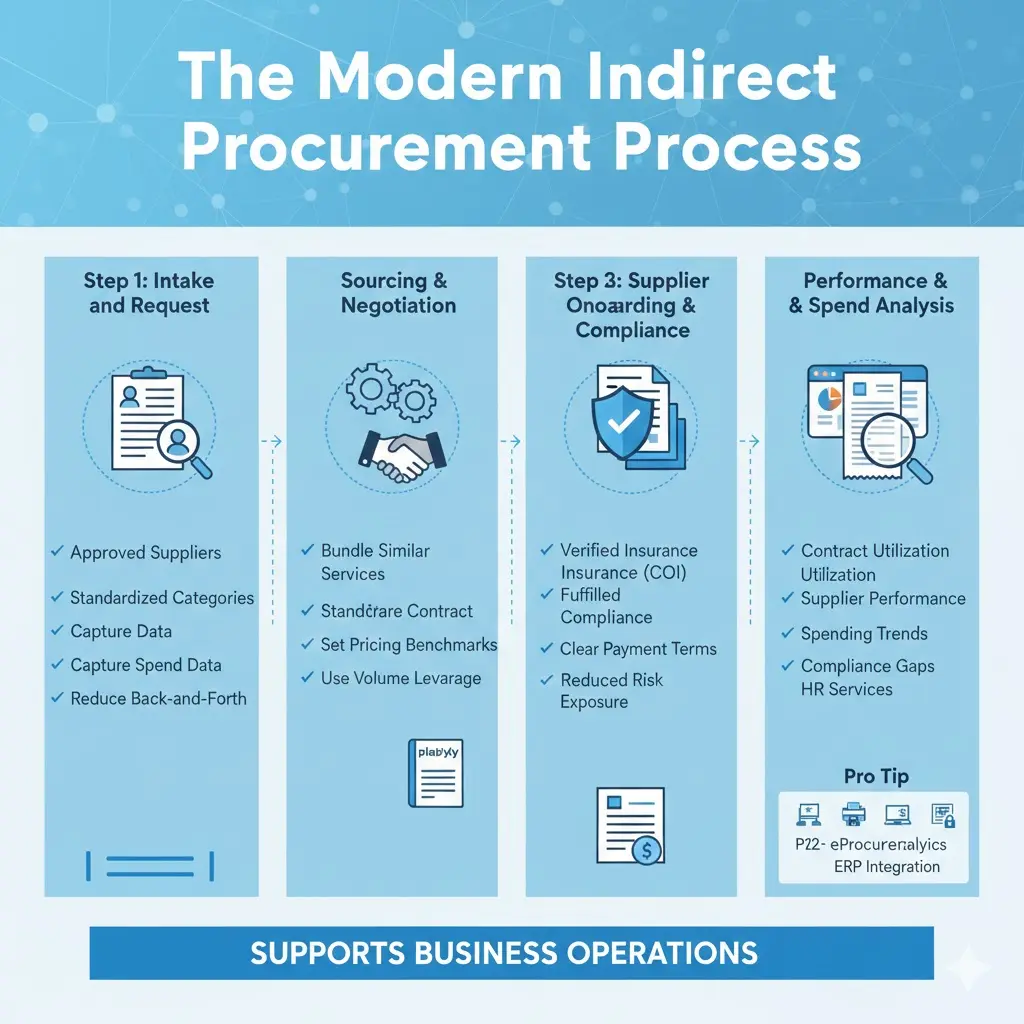

Step 1: Intake and Request

This is where most problems start, or stop. Employees need a way to request what they need without guessing. Here are good intake systems:

- Guide users toward approved suppliers

- Standardize categories

- Capture spend data early

- Reduce back-and-forth

You must think of it like guardrails to streamline the whole process.

Step 2: Sourcing & Negotiation

This is where indirect procurement quietly creates savings without disrupting operations. Well, indirect sourcing is about consistency.

For repeat categories, you should use playbooks, including baseline market rates, target levers (lead time, minimums, guaranteed holds), and fallback suppliers for emergencies. For one-off services, have an RFP template and a pre-qualified panel.

In other words, bundle similar services, standardize contract terms, set pricing benchmarks, and use volume leverage across departments.

Step 3: Supplier Onboarding & Compliance

In this step, you need to verify COIs, tax forms, licenses, safety records, and, for SaaS, ask about SOC2 or equivalent. Agree on KPIs and reporting cadence up front since it eliminates arguments later.

With proper onboarding, you can ensure:

- Verified insurance coverage

- Fulfilled compliance requirements

- Clear payment terms

- Reduced risk exposure

Note: It’s also what prevents legal and financial messes throughout the project lifecycle.

This structured flow of intake, sourcing, and onboarding is exactly what an end-to-end procurement process is designed to standardize and control across organizations:

Step 4: Performance & Spend Analysis

Finally, monitor performance with monthly dashboards. Reconcile claimed savings with invoices. If someone promises a 15% saving but you see no difference on invoices, call it out and fix the assumptions.

Professional teams usually review:

- Contract utilization

- Supplier performance

- Spending trends

- Compliance gaps

So, review all these points and make your plans achievable in the real world.

Pro Tip: Technology is an enabler. Use P2P for approvals and payments, eProcurement for catalogs, CLM for contract renewals, spend analytics to find tail and maverick spend, and integrate with your Procore or ERP so site and central numbers match.

The Role of KPIs & How to Calculate Them?

You can’t improve what you don’t measure. Procurement KPIs are simple and meaningful.

- Contract Coverage: Percentage of indirect spend covered by active contracts. If you’ve got $10M in indirect spend and $6.5M is under contract, you’re at 65% coverage.

- Maverick Spend: The share of purchases made outside approved contracts. Typical impact is in the 10–20% range, which is huge once you do the math.

- PO Cycle Time: How long from request to PO issuance. Long cycles push people into ad-hoc buying and emergency rentals.

- Supplier On-Time % (SOT%): Percent of deliveries that meet the agreed lead time. Uptime wins projects.

- Realized Savings Vs Cost Avoidance: Realized savings = actual invoice savings vs baseline. And the cost avoidance = projected but not yet realized savings based on forecast volume.

- Set a Dashboard Cadence: Daily for critical approvals, weekly for maverick flags, and monthly for coverage and realized savings. Assign owners: procurement tracks coverage and validation; project managers own day-to-day supplier performance.

Governance & Stakeholder Model

Procurement breaks down when people don’t know who does what. Put simple thresholds in place. For example:

- <$500 auto-approve in catalog

- $500–$5,000 department head

- >$5,000 procurement review.

And also require legal services for big retainer services.

The Ideal Systems for Governance & Stakeholder Model

1. Hybrid Model

It is a Center of Excellence for strategy and local procurement for execution. This helps you match construction reality, as local suppliers matter, but a centralized strategy gives you leverage.

2. Create a Stakeholder Rhythm

It includes category champions who pair procurement and construction leads, weekly sourcing syncs, and a pre-bid procurement review to catch expensive gaps before contract awards. Using these strategies, you can save thousands of dollars on unforeseen expenses.

What Contract Clauses are Beneficial

Contract language matters. A few precise clauses prevent the usual headaches, eliminating the issue with…

- Delivery windows with penalties

- Liquidated damages for critical service failures

- Warranty timelines

- Insurance requirements

- Price escalation tied to recognized indices

- Termination for convenience

- Data protection for SaaS vendors

Risk, Compliance & Supplier Due Diligence

Small vendors can create big liabilities. Therefore, it is essential to vet early and automate monitoring. Require W-9s, COIs with expiry tracking, trade licenses, safety records, and references. For SaaS, you can request security certifications.

For ESG and modern-slavery concerns, ask suppliers for a basic declaration. For major vendors, ask for emissions data if they claim sustainability. Furthermore, put a right-to-audit clause in high-risk categories. Also, automate COI renewal reminders and hang payment holds on expired insurance to force compliance.

Strong supplier vetting and compliance controls should always be backed by a formal supplier code of conduct, which defines what ethical, legal, and operational standards every vendor must follow:

The Silent Killers: Maverick Spend & Tail Spend

Let’s talk about where money actually disappears.

● Maverick Spend

Maverick spend happens when employees buy outside approved contracts. Not because they’re careless, but because they’re busy. It is like using a credit card when in need of something now and don’t know where to go. Industry data shows this can cost organizations 10–20% in lost savings.

● Tail Spend

First, get its pattern!

- 20% of suppliers = 80% of spend

- 80% of suppliers = 20% of spend

Hundreds of low-value vendors, high transaction costs, and zero negotiation power are all included in tail spend. If you are considering managing tail spend manually, you will loss the game as it needs to be managed regularly. And this is where automation and AI actually help.

The Role of AI in Indirect Procurement

In 2026, agentic AI tools will handle:

- Vendor discovery

- Quote comparison

- Contract creation

- Low-value negotiations

- Invoice matching

AI is not replacing procurement teams, but freeing them to work on their core jobs. You can picture this as humans are focusing on strategy, and AI is handling the repetitive tasks.

Tail Spend Playbook

Tail spend is fixable. Extract your tail list, including suppliers with tiny spend over 12 months, consolidate duplicates, and create punch-outs or quick contracts for the most frequent items. Also, automate buys under a threshold via catalog and track the reduction in supplier count and PO time.

Usable Tools for Tail Spend

- Aggregator marketplaces

- Punch-out catalogs

- Procurement bots.

Emerging Indirect Procurement Trends Shaping 2026

● ESG and Scope 3 Reporting

Indirect procurement sits right at the front line of sustainability. Why? Because Scope 3 emissions come from suppliers, service providers, and logistics partners

If you don’t control indirect vendors, you can’t measure impact. Today, trustworthy companies, like Pro Procurement, track supplier emissions, enforce sustainability standards, and ultimately, reduce reporting risk.

● Agentic AI

We’re past simple automation. Today, modern systems initiate purchases, negotiate within limits, flag anomalies, and recommend supplier changes. Simply put, you can consider them as your assistant who never sleeps.

● Regional Resilience

Global disruption taught hard lessons, and indirect services are shifting to local maintenance, IT support, and facilities services. Today, they are equipped with faster response, lower risk, and better accountability.

How to Build a Resilient Indirect Procurement Strategy

This is where everything comes together. You must understand that a strong strategy isn’t complex; however, it’s the consistent one. It should include:

- Clear ownership

- Simple intake

- Approved supplier networks

- Ongoing visibility

- Technology that actually gets used

Most importantly, it should align with the methods of how people work.

Case Study

One GC was wasting money on emergency excavator rentals. A company set a regional framework with guaranteed holds and fell from emergency rental addiction to scheduled allocations, saving 18% on rates and cutting emergency rentals by 40%.

How to Handle Indirect Price Variation?

Even indirect categories see price swings. Use indexed escalation clauses, fixed-price windows for peak seasons, forward-buy small consumables for long projects, and negotiate cost-sharing clauses. Simply put, smartly draft escalation language to protect you while being fair to suppliers.

What to Adopt Today?

If you don’t need a full program to get started, do these three things this week:

- Pull 12 months of indirect spend and identify the top 20 suppliers and categories. This is your roadmap.

- Pick one category for a 60-day pilot (rentals or MRO work well) and measure PO compliance and on-time % before and after.

- Create a short catalog for low-dollar buys and set sensible approval thresholds so buying the approved way is faster than the old way.

FAQs

What is indirect sourcing?

Indirect sourcing is the process of identifying, negotiating, and managing suppliers that provide non-production goods and services supporting business operations.

What is indirect purchasing?

Indirect purchasing refers to buying items or services that don’t directly become part of a construction project but are necessary to run the organization.

What is direct and indirect procurement?

Direct procurement focuses on materials and labor used in construction. Indirect procurement covers services, tools, and systems that support operations.

What is the difference between procurement and purchasing?

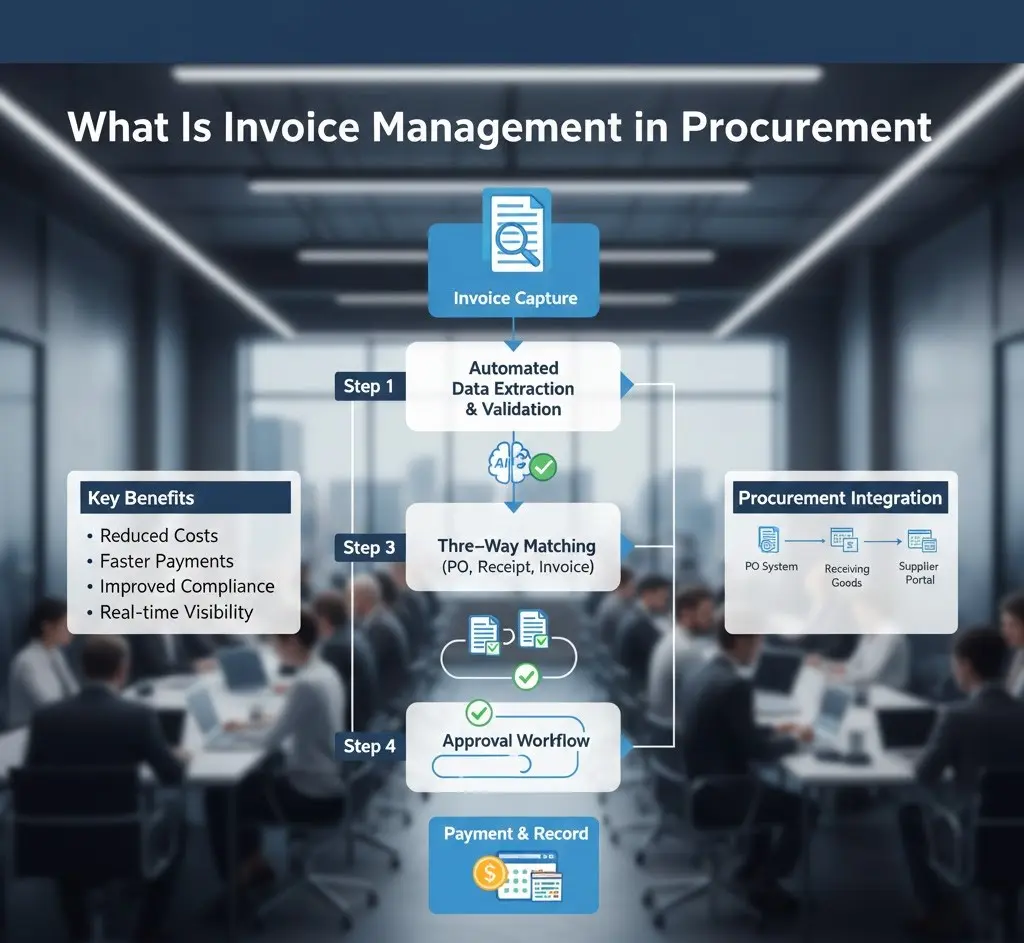

Purchasing is transactional, including placing orders and paying invoices. Procurement is strategic, including managing suppliers, contracts, risk, and long-term value.

Final Words

Nobody wakes up excited to fix indirect procurement. But once it’s fixed, everything else gets easier. Projects run smoother, budgets remain within the limits, and teams stop conflicting.

If you want help building an indirect procurement strategy that actually fits construction, Pro Procurement is ready. Let’s clean up the hidden spend, and put that money back where it belongs!

How Pro Procurement Helps?

At Pro Procurement, we don’t just manage vendors, but we also design systems that cut problems from the plan before they start. In other words, our procurement services will help you:

- Centralize indirect purchasing

- Reduce maverick and tail spend

- Standardize contracts

- Improve supplier accountability

- Gain real spend visibility

If indirect procurement feels messy, hire us and bring everything to the right track!