Procurement is the core of any business. Whether a company is buying raw materials, office supplies, or services, every purchase is a transaction with costs that extend beyond the initial price of goods. These costs, called procurement costs, are critical for determining profitability, efficiency, and ongoing sustainability.

In this blog post, we will take an in-depth look at procurement costs – what they are, some key components of procurement costs, how to measure procurement costs, and an example of procurement costs from a real business. We will also explore ways to measure procurement costs and some recommendations for reducing procurement costs.

What is Procurement Cost?

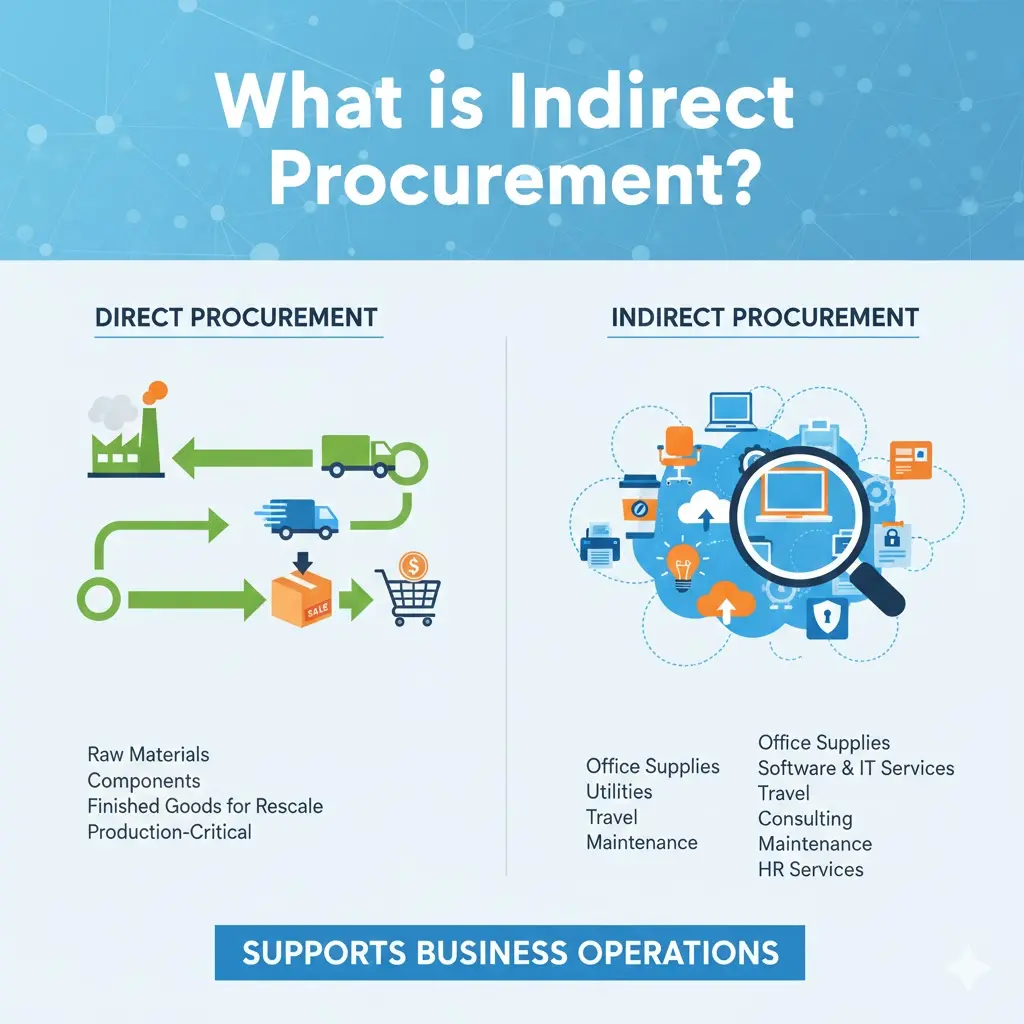

Simply put, procurement cost is the sum of all costs incurred by a company for obtaining goods or services. The greatest misconception is to look only at the price tag, but procurement cost is the sum of both direct and indirect costs. This means procurement cost is not only the price of the goods, but also the costs directly related to purchasing from the supplier, shipping, storage, compliance, administrative costs, etc.

For instance, if a manufacturer purchased steel for $100,000, that is just a price. Once you account for transportation, import duties, storage, employee time to process purchase orders, and legal costs of contracts, the procurement cost may be closer to $120,000.

In short, procurementcost allows businesses to see the true costs of procurement, not just the amount on the supplier’s invoice.

Essential Components of Procurement Cost

Procurement cost is complex. A combination of factors comes together to create the total cost. While there are a variety of component parts to a procurement, the major components can be summarised as follows:

- Purchase Price of the Goods/Services – The most visible and the largest portion, but rarely represents the whole picture.

- Administrative and Operational Costs: Costs associated with order processing, obtaining approvals, and working with suppliers.

- Supplier Evaluation and Selection: Costs associated with researching, selecting, and negotiating with suppliers.

- Shipping and Logistics: Freight costs, fuel costs, and coordinating with a supplier for delivery are very costly.

- Customs and Duties: If you are procuring internationally, you cannot avoid import tariffs and compliance fees.

- Quality Control and Inspection: A variety of costs could be involved in verifying products to ensure they meet quality or acceptable standards – testing, third-party certifications, etc.

- Storage and Handling: Managing inventory incurs additional costs – if your goods require warehousing, there are related costs.

- Employee Time and Labour: A very often overlooked cost of procurement is the cost of employee hours working on procurement tasks.

How to Get Procurement Costs

To obtain procurement costs, it is necessary to consider both direct costs and indirect costs. Though the formulas might differ depending on the type of industry and business size, a simple calculation could look like this:

Procurement Cost = Direct Costs + Indirect Costs

Direct Costs – the purchase price, shipping, duties, and taxes.

Indirect Costs – administration, labour, technology systems, and quality control.

For example, a company sourced machinery from overseas at a purchase price of $50,000. Shipping and customs were another $7,500. In this case, you valued the administration time to source the machinery at $2,000 and put aside another $500 for quality checks. In total, the procurement cost is $60,000.

The trick is getting all costs associated with the procurement cycle. Many businesses that do not take the associated indirect costs into consideration do not understand the extent of their actual spending.

What Are Some Procurement Cost Examples?

The terminology for procurement costs can take many forms in any industry. A sampling of examples is listed below:

Manufacturing: When ordering raw materials, there may be additional costs for transportation, insurance, and inspection, in addition to the cost of purchasing them.

Retail: When importing goods from suppliers overseas, procurement costs may include customs duties and warehousing for the product.

IT Services: When procuring software, you may incur costs for vendor licensing fees, implementation or support staff to implement it, training, and annual maintenance.

Construction: The procurement of materials for construction may be equal to the cost of coordinating the logistics of getting the materials, as well as any permits, and inspection on-site.

These examples show that procurement costs are industry-agnostic, though details may differ….

How to Measure Procurement Costs

Measurement is just as important as calculation. Once businesses have an idea of what goes into procurement costs, they will need to utilise a few methods for capturing these costs over time.

Cost per Order: Total spend on procurement divided by the total number of purchase orders.

Supplier performance metrics: Securing measurement of the suppliers’ delivered quality and value as agreed.

Cycle time: How long it takes from placing an order to final delivery. Timing on deliveries can drive up the cost side.

Spend analysis reports: Reviewing spend and where inefficiencies may lie when comparing suppliers and categories.

Technology can and will help. Modern procurement is going to be using software that can automate a lot of capturing procurement costs, including recording on-time deliveries, which drives towards cost transparency and visibility. Having a software suite that can generate reports for you that can adjust based on variables and metric systems would be a great beginning to capture some historical changes over time. When you capture these expenses, you will become more informed.

Procurement Cost and Procurement Fee

The first thing to differentiate is the difference between procurement cost and procurement fee, and this is commonly misunderstood.

Procurement Cost refers to the total expenses incurred in acquiring goods or services from a supplier, and it includes both the direct and indirect costs incurred.

Contrarily, a Procurement Fee is typically referenced as the fee charged by a third-party service provider, like a procurement consultant or sourcing agent, for carrying out the purchasing process for a company.

So, for clarity with an example, if a procurement consultancy is hired by a business to negotiate with suppliers, the supplier will pay a fee to the procurement consultancy, and this fee portion is part of the procurement costs in total, but not the total procurement costs.

Having this level of understanding will allow you to budget more accurately and interpret financial statements.

Tips to Lower Procurement Costs

Saving on procurement costs is less about penny pinching and more about thinking more intelligently through the procurement decisions we make (and the rationale behind them). When you develop more intelligent strategies, it is not uncommon to see a shift in the perceptions and overall costs associated with the purchasing process.

1. Evaluate and Reduce the Number of Suppliers

The more suppliers you have, the more complexity you have, and the more cost you incur. Reducing the number of suppliers to a manageable list of trusted sources often gives you the opportunity to pursue better pricing and service.

2. Use Technology

Technology minimises manual errors, allows faster approvals, allows visibility into what you are spending, and helps you focus on savings at the strategic level.

3. Think Beyond the Price in Negotiations

It is easy to focus on just the price. But you should also see if your supplier will provide alternative terms such as flexibility, volume pricing, bundled services, and discounts.

4. Understand the Total Cost of Ownership (TCO)

A low purchase price does not mean that you have chosen the cheaper choice. A low purchase price may come back to haunt you down the road! Make sure that you are considering maintenance costs, storage/junk costs, and disposal costs to avoid unfavourable costs not included in the original pricing.

5. Develop Long-Term Relationships with Suppliers

A stable relationship with your suppliers supports or enhances consistency, loyalty, and even improved pricing in most cases.

6. Track and Follow-up

Continuous tracking of your overall spend and supplier performance will always keep you informed if you have an excessive procurement spend or if supplier performance is not meeting expectations.

Procurement costs may not appear to be obvious to management, but they are powerful in affecting productivity and profit. By examining the full range of costs (realising, accurately calculating, consistently measuring, and practically reducing these costs), companies will be able to transform procurement from being another area of waste to be managed into a potential source of value.

In a market where cost competitiveness is fierce, a lower procurement cost can be repositioned into valuable areas of growth, innovation, or customer service. Understanding procurement cost on a level deeper than just purchase price is the first step into effectively managing the financial health of a business, and ultimately the business’s likelihood of success.