Consider yourself in a scenario. You have a bulk of purchase orders, it is late in the project cycle, and all of a sudden, a supplier delay is involved to cause everything to go wrong. Timescales begin to slip, budgets become stretched, and the team is under significant pressure.

This is what most organizations fail to realize: it is not about purchasing materials or equipment; it is about quantifying how well you are doing it. Procurement KPIs come in that way.

Procurement KPIs are the vital signs of a project. They explain what is successful, what is not and what you have to do better. They change procurement to be more of a strategic support that creates savings, efficiency and value.

This guide will deconstruct procurement KPIs, covering what they are, why they are important, their most common types, how to measure them, and how to roll out a working dashboard. Let’s start!

For a deeper understanding of how these metrics fit into the overall workflow, discover the best practices for optimizing your procurement process flow.

What are Procurement KPIs and Metrics

First, let’s clear up the basics. KPIs (Key Performance Indicators) aren’t just numbers on a spreadsheet; they are actionable metrics that help you understand how well procurement is contributing to your firm.

Tracking purchase order cycle time isn’t about counting hours; it’s about identifying limitations, estimating delays, and improving workflow. That’s the difference between a metric and a KPI.

Some metrics are simple outlines, but KPIs tell a story. They show trends, reveal risks, and highlight where improvements generate real value.

Why is there a Need for Continuous Improvement and Benchmarking in Procurement KPIs

You can not improve what you do not measure. Comparing yourself to previous performance or the industry perspective provides you with a point of view.

- Are your procurement cycle times faster or slower than similar projects?

- Are your costs per unit or per project aligned with industry averages?

- Are the suppliers performing as anticipated?

In the absence of constant measurement, you are flying blind. Benchmarking helps set real goals and turn data into useful improvements.

Since continuous improvement often targets efficiency and savings, understanding what procurement costs are and how to manage them forms the foundation of any benchmarking exercise.

3 Pillars of KPIs Procurement

Procurement KPIs can be divided into three large categories.

1. Cost and Financial KPIs

This is the easiest field, and yet the most critical: not to spend money without compromising quality or efficiency.

- Procurement Savings vs Target: This elaborates on how much you have saved in comparison with planned costs.

- Cost Avoidance Metrics: It is the savings obtained by bargaining on better terms or eliminating unnecessary expenses.

- Purchase Price Variance (PPV): It is the real money paid versus the standard or estimated cost.

- ROI of Procurement Initiatives: This shows how to compute the ROI of strategic sourcing projects or supplier development.

Pro Tip: Measure both financial gains, including invoice reduction, and non-financial gains, including RG, and fewer delays.

2. Process KPIs and Operational Efficiency

Efficiency KPIs tell you if your processes are lean, smooth, and repeatable.

- Purchase Order and Approval Cycle Times: Measure the time between request and order taking.

- Inventory Turnover: Make sure that you are not overstocked or understocked.

- Adherence to Procurement Policies: Ensure that approvals, documentation and protocols are adhered to standards properly.

3. Supplier Performance, Quality, and Risk KPIs

The other team is the suppliers. Their reliability directly affects your targeted construction projects.

- On-Time Delivery Rate: Answer the question “Are your suppliers delivering what you need, when you need it?”

- Quality Defect Rate: Determine poor-quality items or wrong shipments.

- Supplier Risk Assessments: Work on financial stability, compliance, and contingency planning.

Types of Procurement Savings

The issue of procurement savings measurement is not merely about relating to invoices; it is about observing the entire effect of procurement on your projects and the results of your construction business.

1. Tangible Savings

They are easiest to trace. Tangible savings encompass direct savings in negotiated discounts, improved contract terms, purchasing in bulk or more efficient sourcing. Physical savings appear on your balance sheet and are usually the first to be sought out by the stakeholders.

2. Intangible Savings

These are not as obvious as they are important. Preventing project delays, minimizing risk and enhancing quality are cost-saving in both money and time. Trustworthy suppliers eliminate the downtime, whereas the quality of materials could reduce the maintenance cost or the rework cost. These advantages do not necessarily transform into dollars, but they have a great impact on the project outcomes.

Strategic Value

The long-term value of procurement is not just cost-saving; however, it has a growth and competitive advantage as KPIs such as supplier innovation, better procurement processes and long-term cost savings. The strategic sourcing has enabled metrics like supplier performance, reduction of lead time, as well as cost avoidance, which give a complete account of value.

For insights into the intangible value generated by robust partnerships, explore the importance of establishing a clear supplier code of conduct.

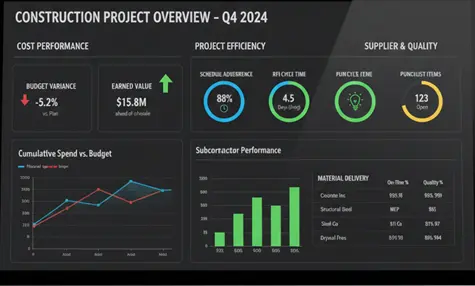

Procurement Dashboard, Reporting and Implementation

Without anyone being able to see them, numbers are meaningless. A procurement dashboard makes sense here.

Key Features:

- Real-time KPI tracking

- Team/executive drill-down reports.

- Alarms in case of anomalies, delays, or non-compliance.

- Exhibited pictures: charts that indicate cost savings, cycling time reduction.

Team and Employee Performance KPIs

Procurement KPI is not a process and supplier issue, but is all about the people who make it happen. Performance measurement on both team and individual bases provides an understanding of performance in terms of efficiency, accountability, and growth areas.

● Personal Contribution Measures

These follow day-to-day performance. The examples are purchase order processing time, error rates, and adherence to internal policies or external regulations. These metrics can be monitored to find out the hurdles and opportunities.

● Training and Development

Employee growth directly influences the performance of procurement. Monitoring the training accomplishment, the development of the skills, and mentoring efficiency is a sign that the team is on the path to develop. Training enhances the team to minimize mistakes and establish stronger relationships with suppliers.

● Accountability and Transparency

Clear ownership is key in procurement. Micromanagement is not promoted through KPIs based on who is accountable for particular tasks or outcomes. The engagement and motivation are bound to rise when team members are aware that their work is contributing to quantifiable outcomes.

So, Giving emphasis to people as opposed to processes makes procurement efficient and strategic. The monitoring of team and personal KPIs, investing in training, and encouraging accountability make the procurement a high-performing unit with employees empowered.

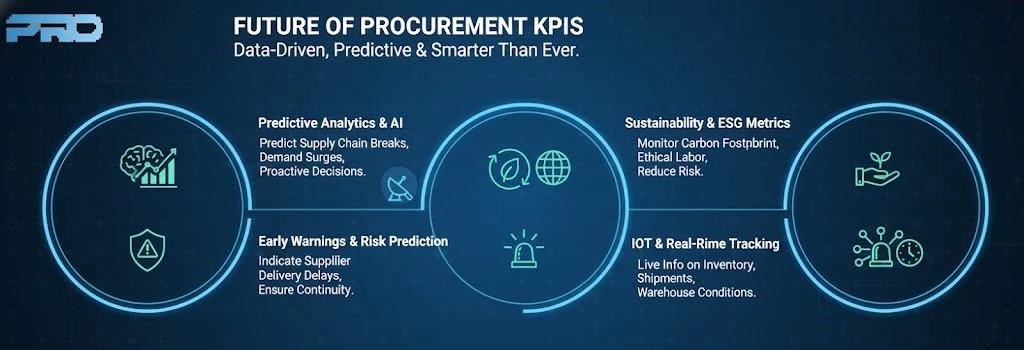

Developing KPIs and Future Trends

The future of procurement KPIs is becoming more data-driven, predictive, and smarter than ever. Advanced KPIs are not limited to conventional cost and process indicators, but they assist companies to remain competitive, reduce risk, and create strategic value in the market.

● Predictive Analytics & AI

Procurement is changing with AI and predictive analytics. Today, they can predict the supply chain breaks, demand surges and fluctuation of costs even before they occur. This enables the procurement teams to take proactive decisions, such as modifying order quantities, renegotiating contracts instead of responding to issues afterwards.

● Sustainability & ESG Metrics

ESG issues are no longer optional. Advanced KPIs monitor supplier sustainability, carbon footprint, ethical labor practices, as well as other social responsibility indicators. The measurement of these will ensure that procurement is in line with corporate ESG objectives and reduces reputational and compliance risk.

● Early Warnings and Risk Prediction

Contemporary tools can indicate possible supplier financial instability or delay of deliveries. The inclusion of these alerts in KPIs enables procurement teams to put risk management on the priority list, ensure supply continuity, and mitigate expensive disruption.

● IoT & Real-Time Tracking

IoT devices such as sensors, GPS and others are connected to give live information into the dashboard to provide real-time information about the condition of inventory, shipments, and the conditions of a warehouse.

● Staying Ahead

Further utilization of the latest KPIs and technologies is the key to future-proofing procurement. With the help of predictive analytics, ESG measurements, risk alerts and real-time tracking, procurement is not merely a support system, but rather a strategic tool that enables cost-efficiency, resiliency, and business value over time.

Ready to transform your procurement from a support system to a strategic asset? Contact us today to integrate next-generation AI in procurement.

Conclusion

Procurement KPIs are not just any numbers; they are the reflections through which you can see value creation, efficiency, and risk management. Using them, you can monitor the appropriate KPIs, make procurement a strategic partner, diagnose and eradicate inefficiencies, enhance the relationship with suppliers, and provide quantifiable cost reductions. Begin small in case you have to select the 3-5 most important KPIs, monitor them regularly, and build on them. And for professional assistance, rely on Pro Procurement!

FAQs

What are procurement KPIs?

KPIs are quantifiable variables that demonstrate the level of performance of procurement.

Why are the KPIs of procurement relevant?

They provide visibility, decision direction, efficiency and measure savings.

What are the KPIs to select in my team?

Target strategic objectives, supplier performance, operation performance, and cost/value.

Which tools will be useful in tracking KPIs?

KPI tracking and reporting can be centralized using procurement dashboards, ERP systems, and project management software.

Here are these:

- Procurement dashboards

- ERP systems

- Project management software.