There comes a time when the pressure begins to build up in every construction project. Raw materials are not coming on time. One of the subcontractors abruptly withdraws. You receive a quote that is not anything like what you were talking about. And you, caught in the midst of all this, attempt to keep the timeline, budget and the team within the schedule on track.

You know, because having experienced such tension, you already know the importance of procurement. Construction does not work on ideas only. It operates on materials, equipment and people, most of whom are not part of your own team. That is what contributes to procurement not being a transaction. It is the system that maintains a project constant. It ensures that the right things are in the right time, in the right amount, of the right quality, by the right people.

Project procurement management is merely the art of ensuring that all that is foreseeable, rather than an accident. And when it is done right, you can tell the difference. Work flows, deadlines hold, teams don’t scramble, and expenses stay under control. Simply put, you are not responding anymore; you are leading. Procurement analytics turns raw purchasing data into clear insights

This instruction takes you through how procurement actually functions on projects, particularly on construction projects, where time, coordination and accountability predetermine everything.

Let’s start with the basics.

Defining Procurement Management

Think of procurement management as the project’s external nervous system. You are creating a systematic track of how your project will acquire anything that it does not produce internally.

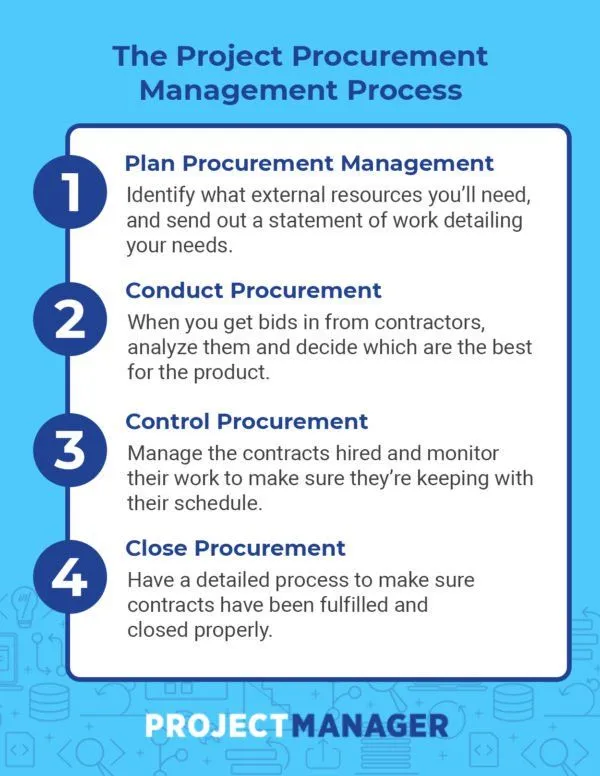

Essentially, procurement management involves four significant topics:

- Planning of what you require.

- Visiting the market to source it.

- Operating the relationship during the performance of the work being done.

- A formal closure of the agreement when the work is complete.

In the construction industry, this involves subcontractors, suppliers of materials, rental equipment companies, consultants, inspectors and specialty trades. A framing contractor, a steel fabricator, a ready-mix supplier, and a roofing subcontractor, every outside party your project relies on passes through procurement.

It is a matter because every one of those vendors influences your schedule, your budget, and your risk exposure. Without a procurement system, you’re reacting to whatever happens. However, with one, you’re directing what happens next.

Why Procurement Management Matters

If you’ve managed or supported a construction project before, you’ve probably seen how easily a small disconnect can ripple into a chain reaction. A delivery arrives late, suddenly a labor team is idle, a permit inspection gets pushed back, and the next trade can’t begin. Before you know it, three other tasks have shifted.

Procurement is the early-warning system that keeps those issues from turning into disruptions.

Benefits of Procurement

● No Need to Wait

The first advantage is that of not having to wait. Planning early, knowledge of lead times, and ensuring that there is sufficient communication with suppliers are some of the things that help the procurement teams to create space to accommodate the unexpected things. Materials arrive when they’re supposed to. Subcontractors know exactly when they’re needed. Instead of firefighting, the schedule stays steady.

● Cost Control

Transparent bidding, clear scopes, and well-defined contracts eliminate misunderstandings that turn into change orders. You’re not paying extra because someone thought something was included. You’re also not jumping into the first quote you receive; however, you’re comparing options, evaluating value, and choosing strategically.

● Risk Mitigation

Procurement minimizes risk also. The failure of suppliers, unreliable quality, fluctuation of prices, and compliance issues will no longer be a significant problem in the case when you decide to examine the vendors well and establish the correct clauses.

● Accountability

Once expectations are written into a contract, performance isn’t subjective anymore. Vendors meet their delivery dates, quality standards, and milestones. And if they don’t, you have documented ground to act.

Complete Procurement Process, from Plan to Close

How to Plan Procurements

Pro Procurement starts with planning. This step will be the foundation of all other steps, hence you would want it to be considerate, cooperative and rooted in actual project requirements.

1. Make a Team

It begins by making the right people come together. Planning of procurement is not a task that the project manager does in isolation. All of these involve engineering, finance, quality, site management, safety and the procurement department. Risks are identified from different perspectives by each group. Once such views are integrated at an early stage, the project will be much more solid later.

2. Understand Project Requirements

The second thing is to determine what a project requires. This may seem easy, but this is where most projects fail due to rushed working. A subcontractor takes the responsibility to do something that a team has assumed they can do, only to find that a vital step has not been mentioned. Or they do not adequately anticipate the lead time for a specialty material.

3. Fill Gaps

An adequate needs assessment compels you to take your time and pose the question: What do we really need to source? What can we handle in-house? What special equipment or capabilities do we lack? This analysis of make or buy is the gap between sourcing and a costly shortcut.

4. Select a Contractor

The next step is to make a selection of a contract type. Both types – fixed-price and cost-plus and time-and-material, and unit pricing – determine the distribution of risk between the contractor and the vendor. Fixed-price contracts provide certainty, which is sometimes needed by construction teams, but are not always suitable in complicated or uncertain scopes. It is aimed to fit the nature of the work with the contract, rather than vice versa.

5. Sum Up

Lastly, all of this is summed up in the procurement management plan. It’s not merely a formality. It’s the blueprint for the entire procurement lifecycle.

When planning is done well, the rest of procurement becomes smoother. This does not mean easier in every moment, but clearer, more controlled, and significantly less stressful.

How to Conduct Procurements

This is the stage where you step into the market. RFQs and RFPs go out, vendors review scopes, questions come in, prices, timelines, and capabilities are compared.

Imagine this stage to be similar to the interviewing of applicants for an important position. You are not in pursuit of the lowest price; however, you are seeking the supplier who comprehends the job, promises to your schedules, and fulfills your quality standards while having an excellent communication system.

In quotation, everything is clear. A vague or hurried scope will be a curse to come back to you. An RFP that is made well with clear drawings, requirements and evaluation criteria will attract a better vendor and minimize misunderstandings.

Vendor evaluation is where experience matters. Construction procurement isn’t just about reading estimates on a spreadsheet; however, it’s about recognizing who can actually deliver. A price might be attractive, but if the vendor has a history of delays or quality issues, that savings disappear quickly.

Once the top vendor is selected, negotiations begin. This is where the contract takes shape. You are setting expectations and agreeing on deliverables, establishing payment terms, clarifying warranty obligations, establishing change order procedures, and establishing schedules. A contract goes beyond a signature; it is a blueprint that the whole team works on for months, even years.

At the end of this stage, you should have a vendor who is fully aware of what they are supposed to do and a contract that covers the project in case something changes.

How to Control Procurements

This is the phase that separates average projects from reliable ones. Making procurements may attract the signing of the contract, but it is the control that makes the work actually meet expectations.

● Project Management

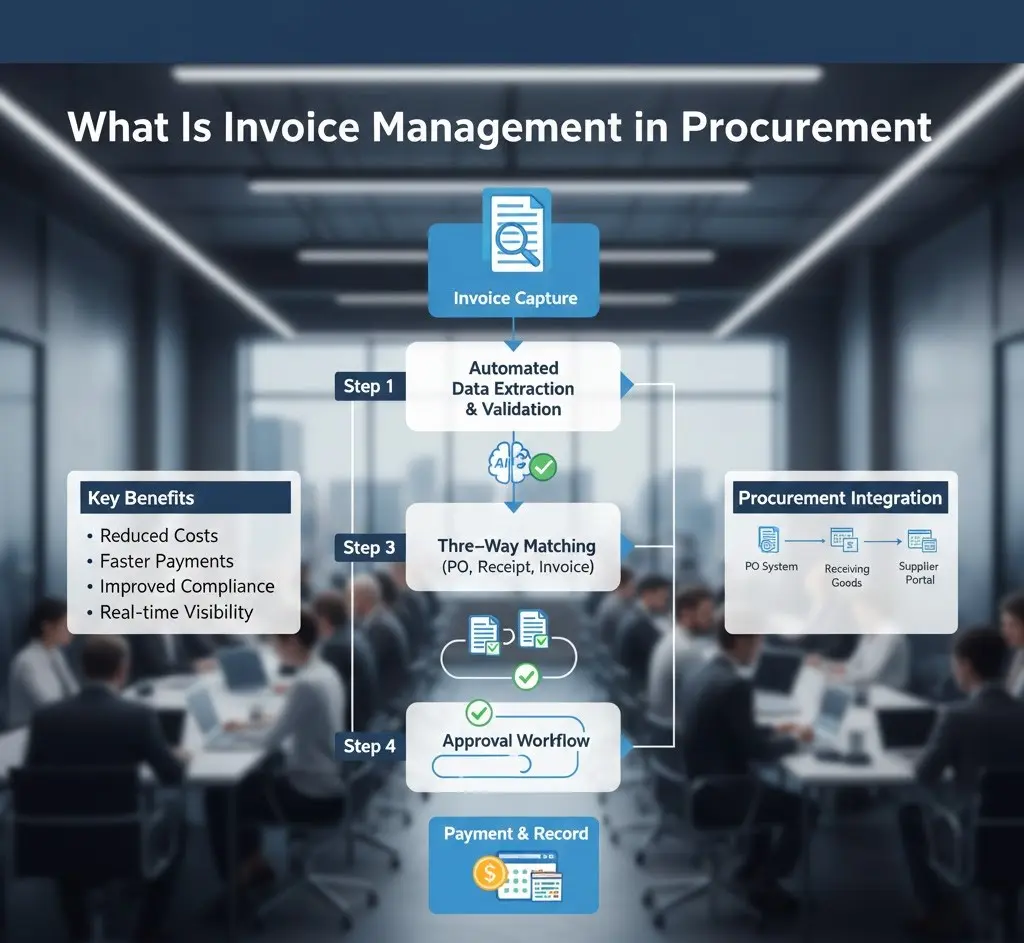

At this phase, the project manager remains heavily engaged. You keep track of progress, deliverables, quality, invoice approvals and schedules. You are also liaising with the site team to identify problems at an early stage. When a delivery is slippy, or before a vendor suffers, you want to know before it trickles down to work.

● Performance Management

Performance management plays a major role here. Instead of relying on gut feelings, you’re watching metrics, delivery accuracy, schedule adherence, inspection results, documentation completeness, and safety compliance. These indicators tell you whether the vendor is performing or drifting off-course.

● Change Management

Change management also becomes important. Construction projects evolve. Sometimes scopes expand. Sometimes conditions change. A good change process ensures that adjustments are documented, priced fairly, approved by the right people, and integrated into updated schedules. Without this structure, you invite disputes.

● Communication

The heart of procurement control is communication. Regular check-ins, progress reviews, and site coordination keep misunderstandings from turning into issues. Vendors feel supported but held accountable. The project moves with rhythm instead of friction.

How to Close Procurements

When all work is done, you formally close the contract. This is the next step that is usually hurried, yet it has its significance.

Closing procurements refers to the checking of the material, the services, the documentation, the warranties, the final signature, and checking that all that has been promised is delivered. You confirm that any remaining payments are accurate and backed by completed work.

A proper close also includes a final evaluation. How did this vendor perform? Should they be considered again? Were there issues worth documenting for the next project?

Closing procurements is where lessons get captured, saving time, money, and removing stress on the next job.

Procurement Department vs. Project Manager Roles

One reason procurement feels confusing on some projects is that teams aren’t always clear about who does what.

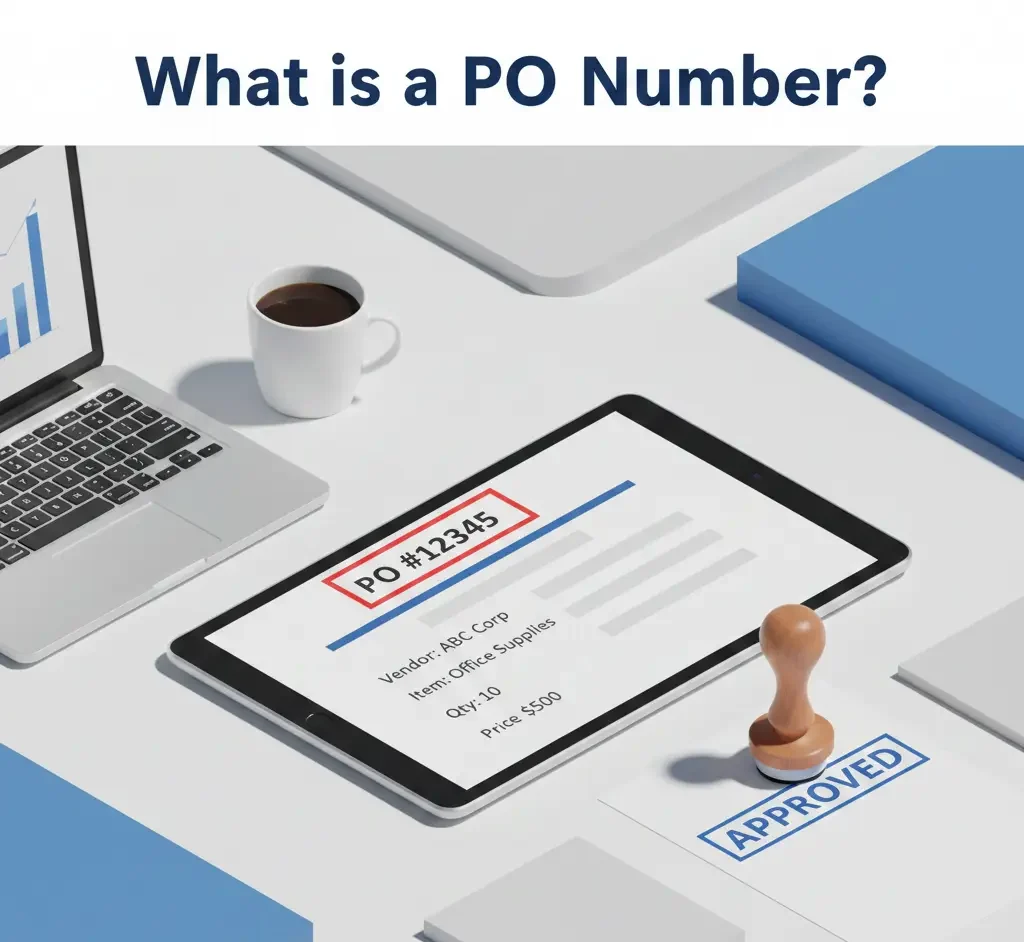

The procurement department focuses on transactions and compliance. They create purchase orders, manage documentation, check for legal and policy alignment, maintain financial records, and ensure auditability. Their responsibility is consistency and proper process.

On the other hand, the project manager handles strategy and delivery. They interpret the technical needs, choose the right vendor in collaboration with procurement, direct schedules, evaluate performance, coordinate with site teams, and make sure vendor work aligns with project goals.

When these roles are respected and connected, projects run with far fewer tensions.

Procurement Risks in Construction

The construction projects have a characteristic set of risks due to the involvement of so many external factors. Even a well-defined work can be disrupted by the bankruptcy of suppliers, shortages in materials, sudden price increases, inconsistency in quality, and unclear scope.

The best protection is early identification and strong documentation. Prequalifying suppliers reduces the chance of picking an unreliable partner. Including price adjustment clauses helps when markets shift. Detailed scopes prevent misalignment. Regular inspections catch issues early.

Simply put, procurement doesn’t eliminate risk, but it makes risk predictable. And that’s what you want as a project manager.

Tools and Modern Procurement Trends

The year-by-year construction procurement is turning digital. Procore, Autodesk Build, CMiC, and Oracle Primavera are some of the platforms that assist teams in managing contracts, invoices, schedules, vendor communication, and change orders through a single platform.

Templates are also significant. A properly organized procurement plan, scoring sheet, RFP format, or change order form saves hours and mistakes.

There is also a trend in the industry towards automated workflows, vendor portal online and real-time price forecasting tools. These projections enhance the ease, transparency, and fast procurement, particularly in complicated projects where numerous vendors are involved.

Understand the Procurement Concept with an Example!

Consider a commercial building of middle size, which requires an HVAC subcontractor. The team starts with the identification of the scope and making decisions that this specialized job should be outsourced. They develop an RFP, collect bids and not only compare prices but also experience, capacity, safety records, and schedules.

They then negotiate the contract with the selected subcontractor, and they define the roles and schedules. In the course of execution, the project manager will track progress, s/he coordinate inspection, and the invoice can be approved only after checking the work done. Once all the installations and testing are complete, a contract is officially closed, warranties are recorded, and a performance review is also appended to the vendor database.

Conclusion

Project procurement management provides the construction teams with one thing that is invaluable: control. Not the inflexible one, but that one that keeps projects on track, teams on track, vendors responsible, and that keeps budgets intact.

Once you know procurement, you begin to see the problems before they arise. You build stronger relationships with vendors. You make better financial decisions. You avoid confusion that often leads to disputes. And above all, you complete your projects with much less stress.

Need templates, support in vendor assessment or assistance in developing your procurement strategy? Contact us for an effective procurement partnership!

FAQs

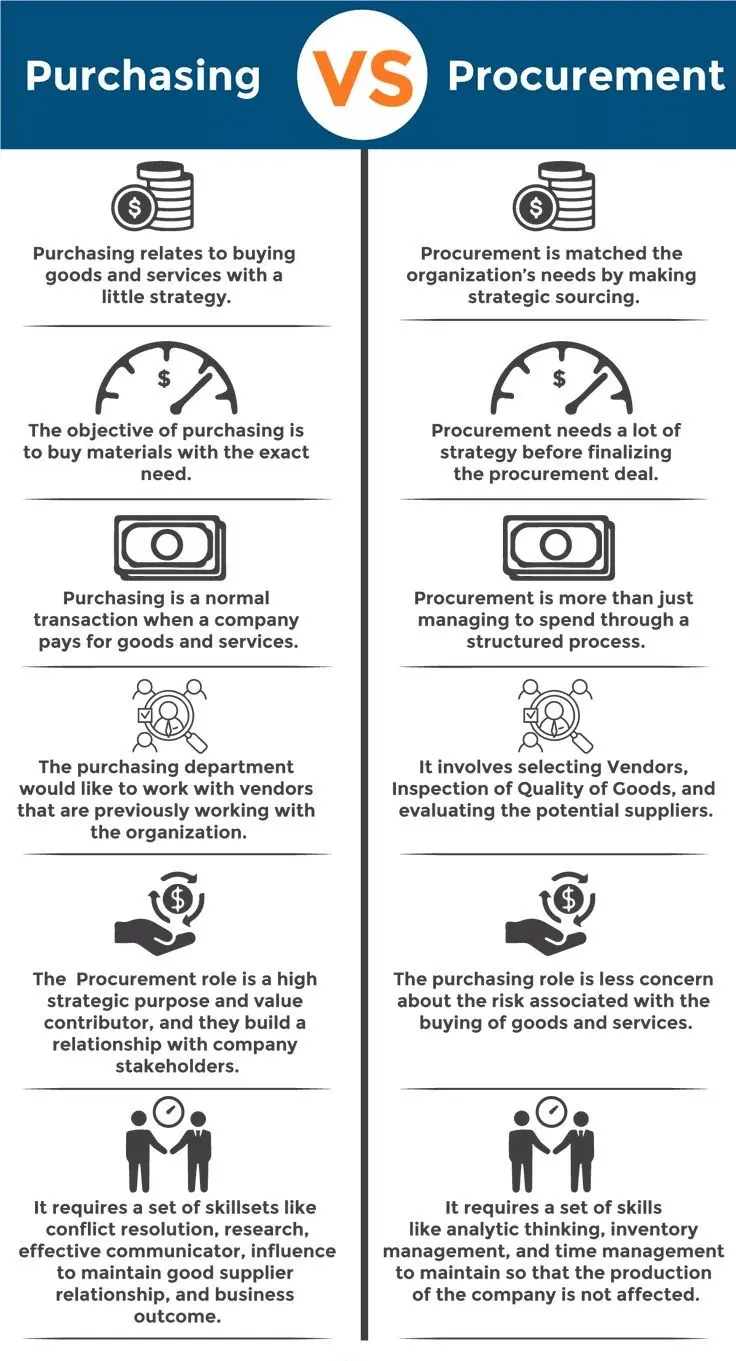

What’s the difference between procurement and purchasing?

Purchasing is a transaction. Procurement is the entire strategy, from identifying needs to selecting vendors, managing performance, and closing contracts.

How do you select the right contract type in construction?

You choose based on risk, scope clarity, and the nature of the work. Predictable work suits a fixed price. Evolving work suits cost-plus or time-and-material.

What’s the biggest procurement risk in construction?

It is vendor reliability. A low price can easily turn into a high-cost problem if the vendor can’t deliver.

What documents are essential for procurement?

Scopes, drawings, RFP/RFQ packages, evaluation criteria, contracts, change order logs, delivery records, invoices, and closeout documents.

Who owns procurement—the project manager or the procurement department?

Both. Procurement handles the process and compliance. The PM handles technical alignment and performance.