Procurement is the most important function within any organization. It encompasses the acquisition of raw materials and services, supplier relationship management and proactive monitoring of delivery schedules to outline the organization’s operational functions. In recent decades, procurement has evolved from a transactional back-office process to a strategic enabler of cost containment, risk mitigation and operational efficiency. As procurement continues to evolve, “end-to-end procurement” has become a holistic approach that challenges previously established norms and reconceptualizes how organizations undertake supply chain activities.

This blog will discuss what end-to-end procurement looks like, why it matters, the process stages of implementing this methodology, and how organisations can gain efficiencies and grow by implementing end-to-end procurement.

Comprehending End-to-End Procurement

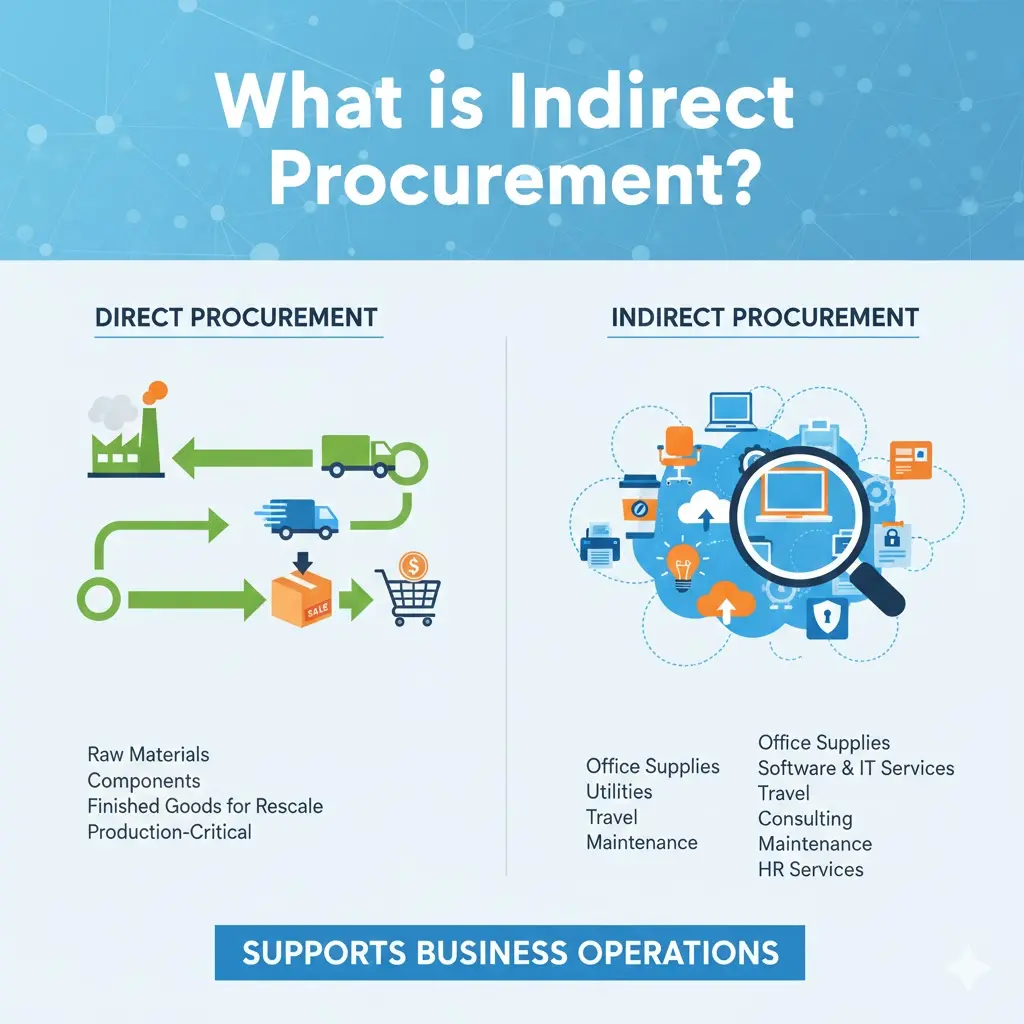

End-to-end procurement is the total procurement cycle and involves each function a company needs to purchase goods or services as it relates to its business first from the requirement a business identifies the requirement, to the final payment and evaluation of the supplier’s performance. The difference between traditional procurement methods with regard to the end-to-end method is that the scope is often limited to some portion of the procurement cycle, for example, purchase order generation or invoice payment. End-to-end procurement involves all details in the chain of obtaining goods or services.

It involves:

- Identifying requirements

- Identifying suppliers

- Evaluating suppliers

- Negotiating contracts

- Generate/purchase order

- Delivery and quality

- Invoicing and payments

- Supplier management

When an organization has visibility and control over all stages, it has transparency, accountability and can ensure long-term value creation.

Stages of End-to-End Procurement

End-to-end procurement typically has a set of stages. Each stage is important to ensure that an enterprise achieves a sustainable and efficient procurement method.

1. Requires Identification

The first stage is understanding the needs of the enterprise, which could be anything from raw materials, services, to goods. Specification and clarity on needs are important so mistakes or costly changes do not occur further along the cycle.

2. Supplier Assessment

Once an enterprise has identified its needs, there will be an assessment for potential suppliers. Assessments will include reputation, price, ability to deliver on time and other things such as regulatory compliance and sustainability policies. Supplier selection will also set the tone for how that part of the procurement cycle will unfold.

3. Contract Negotiation

When a supplier has been selected, the negotiations will determine price, what the payment schedule will be, delivery schedule, warranty details, service conditions, risk management terms, etc. A good contract will hold both parties accountable for their respective actions, thus exposing any opportunities for dispute.

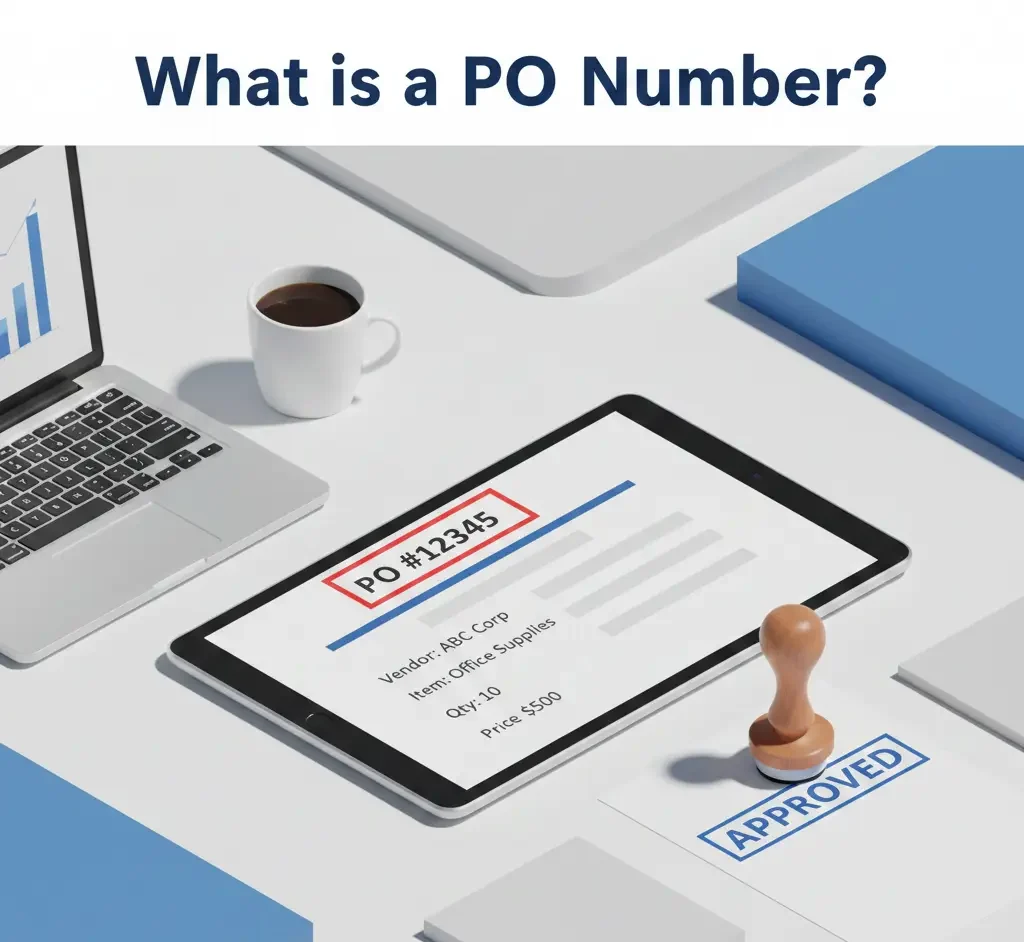

4. Purchase Orders Admin

This part of the process will deal with issuing the purchase orders, making sure the terms meet the contractual details and checking order details with the supplier.

5. Receipt and Inspection

Goods and services are received as specified in the contract. Quality inspections are done to ensure the specifications are met. If not, appropriate corrective action is taken.

6. Invoicing and Payment

Vendor, in accordance with the purchase order, is simply requesting payment for the goods and services provided. The procuring department confirms that the purchase order and delivery receipts match the invoice and approves the invoice for payment.

7. Supplier Performance Management

A procurement process does not end after payment is received. Supplier performance is monitored on an ongoing basis to assess reliability, quality, and efficiency. Conducting supplier communications for feedback is an avenue toward long-term relationships.

Altogether, all of these components represent a closed-loop procurement process that improves compliance, minimizes errors, and continues to create efficiency.

The Value of the End-to-End Procurement Process

An end-to-end procurement process is not just a transaction management process — it will have strategic implications for an organization.

Cost Control – Organizations can view all of their procurement activities when purchasing, which helps to identify inefficiencies that result in unnecessary costs.

Risk Mitigation – Continuous tracking of procurement in the supply chain creates visibility that helps an organization spot possible risks such as supplier insolvency, compliance failure, and delays before they become painful to an organization.

Process Optimization – If the procurement process works and is tracked at every single stage, it reduces the time of bottleneck delays, as well as duplicated effort and wasted time people work independently on the same procurement process.

Supplier Relationships – The big view of procurement creates overall more transparency, thus facilitating trust with all suppliers to increase long-term relationships and collaboration.

Business Growth – When procurements are smarter, quicker, and more efficient, it allows the organisation to have the means available when needed to continue to protect future projects and productions disrupted by the supply chain.

In conclusion, end-to-end procurement takes operational trying processes and turns them into a strategic advantage for the organisation, and creates better overall processes.

The Significance of Technology

Technology serves as a major asset in facilitating end-to-end procurement more efficiently. Various technology options allow organisations to utilise digital platforms, cloud services and automation tools to facilitate their procurement process more effectively and efficiently.

The aforementioned contributions of technology include:

Automation of Routine Reminders – Employees can find the reminders from recurring tasks such as processing orders, invoice matching and data entry with automation, resulting in employees’ time and energy saved and reducing errors.

Data Analytics – Organizations are likely to understand spend patterns (products & services), supplier performance and low-hanging opportunity trends -> Lead procurement teams to influence better information and be strategic in voice with suppliers.

Real-time Tracking – Organizations will be aware of the status of their orders and deliveries within a real-time context, allowing for faster responses and fewer delays to goods arrival.

Technology-backed Communications Tools – Technology creates more transparency and better buy-side seller relationships with procurement personnel.

Functionality with Enhanced Options Across Business Lines – Technology creates procurement systems with integrations to finance systems, logistics and inventory systems – leading to functionality across business lines.

Technology can enable organisations to shift from manual procurement operations to a procurement digital platform.

Approaches to Improve the Procurement Process

To aid the implementation of end-to-end procurement, organisations should adopt established best practices.

Standardize Processes: This practice removes ambiguity and leads to compliance across the organization

Centralize Data: A single view of all procurement data will allow for more transparent decisions.

Invest in Supplier Relationships: Building relationships can lead to better pricing, availability, and creativity.

Follow Compliance: Compliance with legislation and ethics is always in an organization’s best interest.

Ensure Continuous Improvement: Regularly assess your processes and find efficiencies along the way.

Ultimately, best practices convey to stakeholders that you are undertaking a transparent procurement process and building credibility and trust through your procurement efficiency, policies, and practices.

How To Execute End-to-End Procurement

Executing the solution requires a disciplined and phased approach. Organisations need to take into account and be deliberate in taking the following phased approach:

Evaluate Existing Processes – Start by evaluating current procurement practices (e.g. processes, practices, policy) according to the nature of both procurement practice and to identify where procurement is inefficient by conducting a gap analysis (e.g. layering, duplication, excessive approvals).

Establish Targeted Goals – Establish targeted (eg, reduce the procurement cycle time; improve supplier reliability) and measurable goals.

Choose Appropriate Solutions – Choose procurement software solutions that integrate well with all other organizational systems and processes and are scalable.

Train Everyone – Organizations are encouraged to train their people well so they can adapt to the new systems and practices, and technology.

Engage Suppliers – Establish relationships with suppliers and inform them with respect to what the new system and processes will look like, and what their participation will entail relative to expectations and complexities of the software system.

Track progress and improve – After launching the new procurement system, track all outcomes of procurements related to targeted goals, and continue to improve in an iterative fashion.

Having structured rollout plans results in diminishing resistance, increasing engagement, and increasing the chances of sustainable change.

Conclusion

End-to-end procurement is more than a process; it is a strategic framework that allows organisations to control their supply chains, minimise risks, and optimise efficiency. It encompasses the entire process from recognising the need for a material or service to selecting a supplier. By utilising an end-to-end procurement management process, there will be no unintended gaps or inefficiencies in any part of the procurement solution.

Organisations that commit to end-to-end procurement will have the capacity to create long-term growth potential, more collaboration with suppliers, and improved competitive positioning in their industries. Ultimately, with the right strategy and tools, procurement becomes a key enabler of business success.

Frequently Asked Questions

1. What is the difference between end-to-end procurement and procure-to-pay (P2P)?

Procure-to-pay focuses only on key aspects of the transactional part of procurement (purchase orders, invoicing, and payment). From the perspective of procurement, end-to-end procurement is broader and encompasses the entire lifecycle of procurement steps from identifying a need all the way through supplier performance monitoring.

2. How can technology help streamline the end-to-end procurement process?

Automating repetitive, time-consuming tasks frees up procurement personnel to engage in value-returning activities (i.e., leveraging supplier relationships). Technology provides real-time visibility into procure-to-pay timelines, which improves operational performance and data accuracy. Enhanced collaboration with suppliers improves alignment with procurement requirements and supplier performance. Engaging technology that integrates procurement with finance and supply chain systems improves overall procurement performance through reduced errors and the elimination of delays.

3. What is end-to-end procurement outsourcing?

End-to-end procurement outsourcing is when an organization engages a third-party provider to manage the portfolio of tasks throughout the entire procurement lifecycle. Outsourcing allows firms to focus on core operations while benefiting from the outsourcing supplier’s expertise, technology, sales and operating efficiencies.